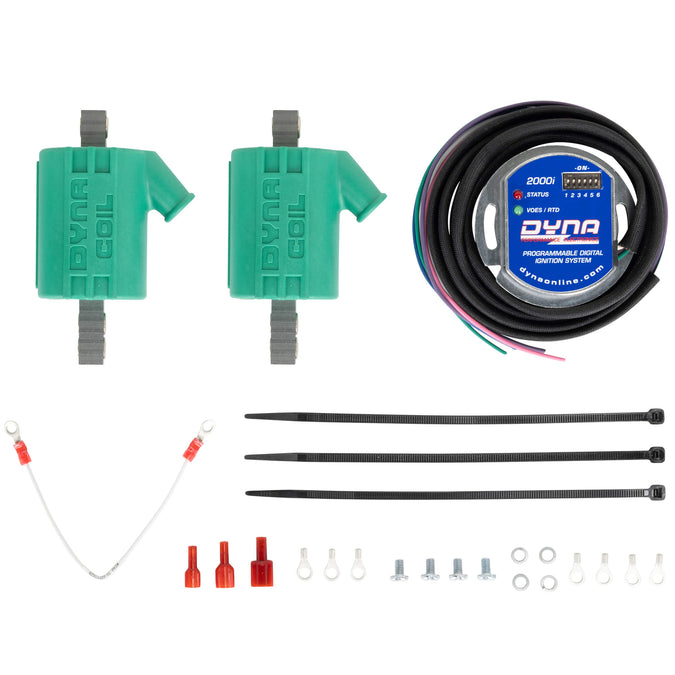

Featuring single fire operation down to 0 RPM for easier cranking and kicking, the Dyna 2000i will operate in all combinations of single fire or dual fire with single plug or dual plug heads (when used with appropriate coils). The Dyna 2000i’s built in tach driver delivers stable tach signal, even during rev limiting or can be used to activate shift lights, auto shifters, and other accessories.

This module features data recording, keeping track of total engine hours, time at wide open throttle, number of engine starts (2 minutes running counts as one), longest time operating at wide open throttle, maximum RPM, seconds near rev limit and statistical analysis of time at RPM.

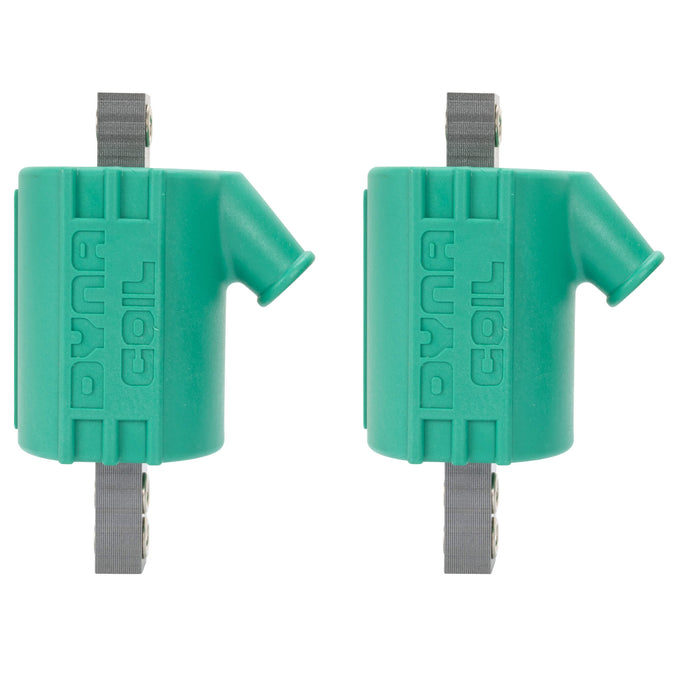

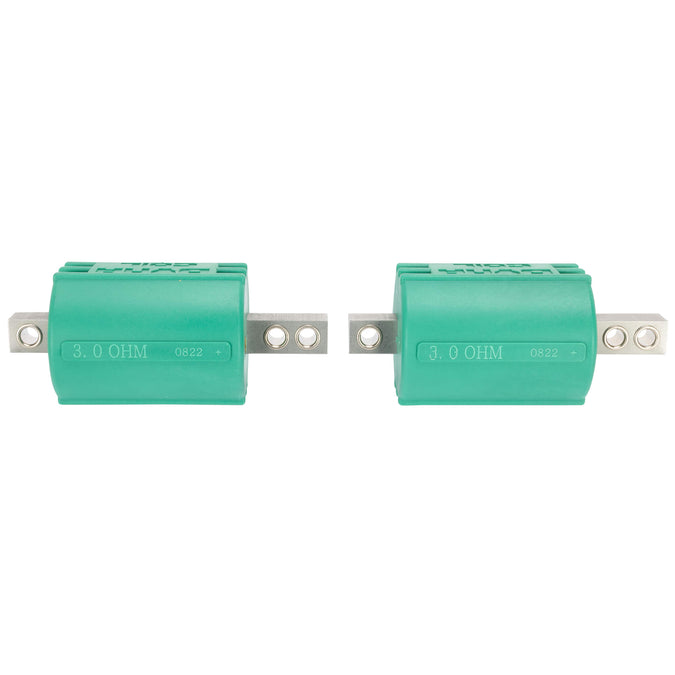

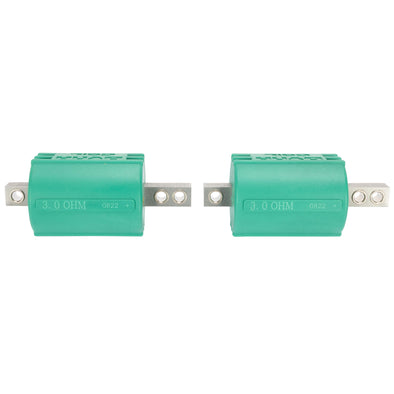

Every time power to the ignition is switched on, the 2000i will check to see if the coil is shorted, mis-wired, or the wrong type. If an error is detected, the 2000i will immediately switch off and issue a warning by rapidly flashing the status indicator. Besides protecting the unit, this also prevents the costly failure of an improperly matched coil going bad one hour into your ride. After starting, the 2000i continuously monitors the 3 Ohm Dual Fire Coil (not included) and wiring status.

With active dwell control, the module continually adjusts coil current to maintain maximum spark energy all the way to redline while eliminating coil stress caused by overcharging at idle. High efficiency design reduces battery draw for easier cold weather starting and lower charging system load.

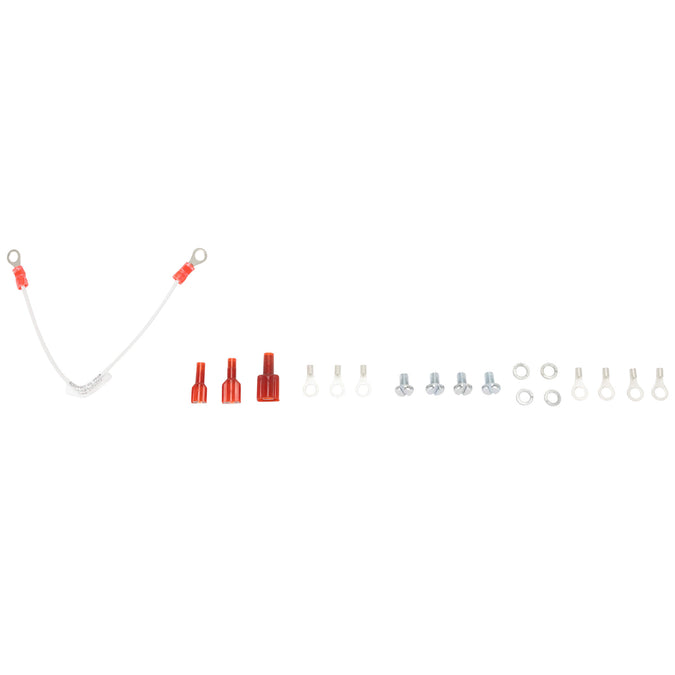

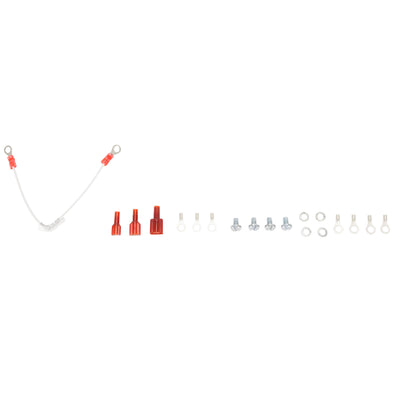

The Dyna 2000i was built to last — it cannot be damaged by broken or disconnected spark plug wires. The harness was constructed with TXL cross linked polyethylene automotive wire for exceptional resistance to abrasion, heat, and chemical attack. High temp glass braid jacket further increases the toughness of the harness and provides a tight, clean appearance. Wire colors closely match the factory harness for error free installation. For fitment see Additional Information below.

The DYNA 2000i Digital Ignition is designed to replace the factory ignition module and sensor used on 1983 and later Harley-Davidson EVO motors. ( Not for fuel-injected models)

Completely self-contained so entire unit hides under the cam cover for a clean look on custom bikes

Single-fire operation down to zero rpm for easier cranking and kicking

Will operate in all combinations of single-fire or dual-fire with single-plug or dual-plug heads

Ten advance curves cover a broad range of engine builds and riding styles

Engine over-rev protection, adjustable from 6000 to 7500 rpm

Adjustable timing retard for nitrous and turbo applications

VOES indicator lets you monitor VOES switch at a glance

Built-in tach driver can be used to activate shift lights, auto-shifters and other accessories

Easy static timing with built-in timing indicator

Intelligent over-current/short-circuit protection

Active dwell control

Over-voltage protected against momentary spikes

Data recording includes total engine hours, time wide-open throttle, longest time operating at wide-open throttle, max rpm, seconds near rev limit and number of engine starts

PC programmability makes possible an eight-point, fully definable, wide-open throttle curve and a fully definable part throttle curve, rev limit programmable in 50 rpm steps, programmable dead-cranking revs 0-5, rear cylinder offset, total of +/- 10°, programmable rev limiter, security lock out (pin # activated), single or dual fire

Programming and downloading data and graphs from module requires proper programming kit (includes CD, cables and instructions)

Pigtail connector (not included) enables the user to connect the ignition to a PC to either download recorded info from the ignition or program their own power curves, rev limits, dead revs or rear cylinder off-set timing; connector remains on bike

Made in the U.S.A.

Programming kit is not necessary to use all selectable functions of the current ignition.

NOTE: To install a 2000i on a kick start motors will require reprogramming the dead revs back to zero (0). Out of the box, the 2000I has 3 dead revs like a stock Harley-Davidson System. This is also a benefit for high compression motors using an electric starter. The kick must not start on the compression stroke (sensor in the window on the cup). Stopping ‘in the window’ will execute the soft turn off. The leading AND trailing edges of the window must be seen by the 2000i to make a spark. That will require a harness to reprogram it you would need Dynatek part # DIPK-1 to reprogram it

Note: There are no returns on carburetors, electrical items, full frames, hardtails or made-to-order items (such as magnetos) unless there is a manufacturer’s defect.

Read more