TIM STATT'S HIGH CALIBER HARLEY EVO CHOPPER

Late summer 2019 Biltwell sent out the word that the Peoples Champ chopper contest was kicking off. I had a bunch of parts lying around and figured I would showcase that we can build a chopper to the same caliber as we do the FXRs (more details from Harley-Davidson model codes), that we normally build.

I submitted photos and a written plan to Biltwell and waited for the results of who would be chosen. We were picked as one of the 13 builders that would be pared down to one single bike “The Peoples Champ”.

We started collecting parts and laid out plans for the bike that I had described on the entry form for the competition. By the time the second round of photos were due we just had scattered engine components, a fender, and crusty wheels. Not much to show off to get people to vote in our favor. We didn’t make it to the next round of voting.

What to do now? I had a frame being modified and some random parts! I didn’t really need another bike and this project was going to take some time and money to complete. I pondered a month or so and decided to build the bike anyway with a few modifications from the original design.

No matter what style bike I was building I needed an Engine and Transmission. I located a low mile 5-Speed transmission at a swap meet. I also had an 80-inch evolution engine that was blown up, sitting on the shop floor with internal damage.

I disassembled the motor to find a destroyed piston and bent connecting rod. I split the cases an rebuilt the bottom end with new parts. The heads looked good but needed a couple of new valves. We dolled up the outside and replaced the oil-pump along with assembling the motor with a fresh coat of powder on the exterior surfaces.

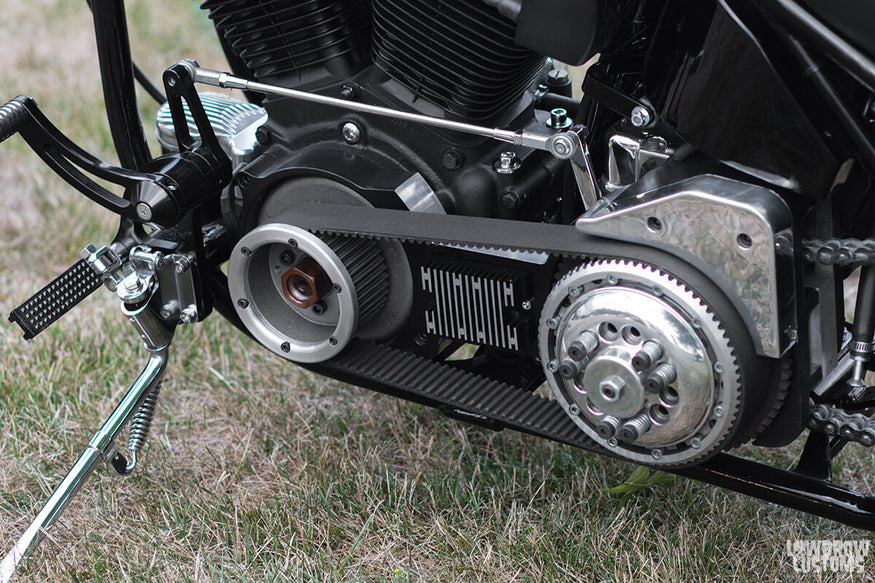

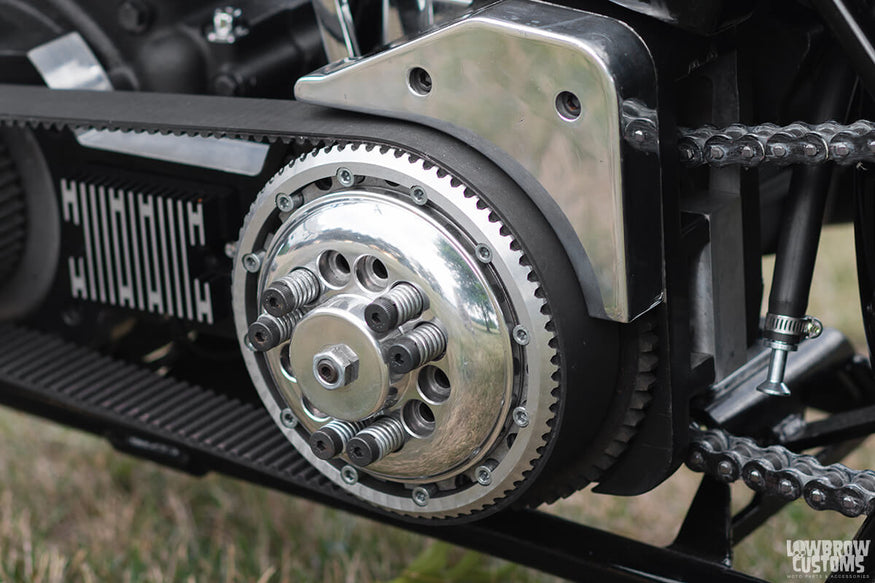

The transmission was inspected and found to be in excellent shape. I had a BDL 3 inch open primary that I bought at a swap meet that needed a little TLC and some mods to work with my plan. The drive line was now complete.

Is a chopper really a chopper with a stock dimension frame? The answer is no! I got on the phone with Mike at 47 Industries and explained what I wanted to do. He had a customer that had a Harley Evo engine Softail that was in a wreck and the frame was available for sale. He went on to explain once you cut off the rear section and hardtail the frame the overall dimensions are really close to a rigid panhead frame.

As I mentioned earlier, I didn’t want a stock framed chopper. Mike added 4 inches to the front down tubes kept the rake at 30 degrees and tied the upper frame tube together to the seat area. The work is superb and looks better than if it came out of Milwaukee. I also had him add some X Bracing in the rear section to add a little attitude.

Once the frame was completed, I had the skeleton to hang the rest of the parts on. Dr. Matt is the guy behind the scenes that gives me a hand fabbing and an opinion on the direction of the build. We work well together as our skills are complementary to each other.

We got the rear wheel lined up and the drive line installed. Next on were the other parts including the rear fender, front end, oil tank and seat pan. This took a couple of nights after work per week and bunch of Saturdays to complete.

We figure we had at least 6 months to complete the bike. Little did we know that after the fabrication was complete, we would have a year and a half to finish as Covid was shutting down the country.

Photo by David Carlo at Fuel Cleveland 2021

Photo by David Carlo at Fuel Cleveland 2021

This project sat in limbo from March of 2020 till August of 2021 when we picked it back up to compete it for the Fuel Cleveland show November of 2021.

August to November seemed like a long time until I started working. The time flew by! Dr Matt took the sheet metal and frame to his shop to lay the glossy coating of paint. In the meantime, I shaved the fork legs of the fender tabs, modified the vintage Henry Abe wheels to work with modern brakes, bearings, and seals.

The swap-meet BDL primary set up was a little beat up and needed some parts. I didn’t like the 3-inch-wide belt, it reminded me of the early 2000 cartoon choppers. I cut down the width of the pulleys to 1-3/4 and sourced a belt to match. The primary backing plate was modified to retain the voltage regulator and add some style.

The rest of the assembly went smoothly however, when you are assembling a brand-new motorcycle, things seem to go slower than you anticipate. I figured I had a week of wiggle room for assembly.

I misjudged and worked 16-hour days for the last week and ended up getting up at 4 am on the day of load-in to get the final details completed to make the trip to Cleveland. The effort was worth it! I made the show!

This bike is a departure from our normal build platform, it has a little hot rod interjected. From the stitching on the custom Harley seat to the tank color and stripes pay homage to a 1970 Boss 302 Mustang Racecar. The minimal chrome and bare aluminum continue this theme.

This bike isn’t over the top with crazy ideas or gimmicks! It’s just a grouping of complementary parts that work well together, anyone with basic mechanical skills can replicate a similar bike using Lowbrow motorcycle parts. This bike was created using swap meet parts and imagination. It's not how much money you spend its where you spend it!

Words by: Tim Statt

Photos by: Lisa Gresens

Grip it and rip it!

Grip it and rip it!

THE YELLOW BOSS TECH SHEET

General

Owner: Tim Statt

Year/Make/Model: 1992 Harley Davidson Chopper

Fabrication: Tim Statt / Dr Matt Coburn

Build Time: start to finish 2 years

Ride Motorcycles Eat Ice Cream

Ride Motorcycles Eat Ice Cream

Engine

Year/Type/Size: 1992 Evolution 80 inch

Carburetor: CV

Exhaust: Lowbrow Supermeg for a Softail 2 into 1 header

Air Cleaner: modified KN

Full Custom hard tailed frame by 47 Industries

Full Custom hard tailed frame by 47 Industries

Frame

Year/Type: 1992 Softail

Rake/Stretch: 0 rake 4 up Hard-tailed by 47 Industries

6" over 39mm front end, Narrow Glide

6" over 39mm front end, Narrow Glide

Front End

Type / Brand: 6” over 39mm narrow glide

19" NOS Henry Abe with Continental Tires

19" NOS Henry Abe with Continental Tires 16" NOS Henry Abe with Continental Tire

16" NOS Henry Abe with Continental Tire

Wheels

Front Size: NOS Henry Abe 19” with Continental tires

Rear Size: NOS Henry Abe 16” With Continental tires

That Boss Yellow paint

That Boss Yellow paint

Finish/Paint

Paint by: Dr Matt Coburn

Plating/Polishing: Gigacycle Garage

Powder coating: Leland Powder Coating

Counterbalance Cycles with the seat!

Counterbalance Cycles with the seat!

Accessories

Front Fender: None

Rear Fender: 4-3/4" Manta Ray Fender

Gas Tank: Narrow Frisco Sporty Gas Tank

Handlebars: Custom T-Bars Jay at Special 79 fab

Grips: Biltwell Grips

Mirrors: None

Hand Controls: Stock HD modified

Foot Controls: Billet forward controls and Biltwell Footpegs

Headlight: 5-1/4 Sportster

Taillight: Biltwell LED Sparto

Turn Signals: none

License Mount: Biltwell

Seat: Custom pan with foam and cover built by Wes at Counterbalance Cycles

Custom & Special Details or Accessories:

4 piston rear brake mount by Gigacycle Garage

Custom BDL Belt drive modified for 1.75 wide belt.

Related Products