TABLE OF CONTENTS

Racing at Bonneville Speedweek 2012, I reached a top speed of 121 mph before throwing a rod on this run. After setting class records at Bonneville Speedweek in 2011 on my 1968 Triumph I found the chassis I was using, a stock front frame and David Bird Triumph hardtail, was about at its limits aerodynamically. I decided for 2012 to build a brand new chassis which took maximum advantage of the rules in the class I was running, partially streamlined special construction. That is basically a purpose built race bike with partial streamlining (fairing or bodywork).

I sat down and made some napkin sketches and talked to David Bird about a brand new full frame which he brought to life. I then set about all the fabrication to make this frame into a land speed race bike. The finished product was something I was very proud of, it definitely stretched my abilities mechanically and fabrication wise. We took the bikes out to the salt flats and I started out strong, increasing speeds each run until on my birthday, August 15th, I threw a rod and windowed the cases in top gear, locking the rear wheel up.

The completed original bike at the old Lowbrow building in Medina, Ohio.

The completed original bike at the old Lowbrow building in Medina, Ohio.

I was lucky and did everything right, pulling in the clutch and throwing my body weight to stabilize the bike and pulled off the race course around mile one. It wasn’t until I stop that I realized how severe the damage was, I had a large hole in the side of my case and oil was pouring out everywhere. Needless to say that was not something I could fix in the pits and my racing was done for that year. In the meantime another competitor in my class took my standing record and push it beyond what I felt I could accomplish with this motor.

Time to tear her down!

Time to tear her down!

I quite literally shelved the bike, never even disassembling it to discover the exact failure and the bike sat in our warehouse a couple years. Every once in a while my brother Tyler or someone else would ask when I was going to do something with it, and I had no answer.

That may be part of the issue!

That may be part of the issue!

Most things come down to time and money, and racing is no exception; if anything it’s the perfect example of this. You spend a ton of money and an entire year preparing a bike to race for just one week (or as long as you can keep it together), and even after all of that work sometimes the weather can still shut down racing, as it did in 2013, and you have to wait an entire year to try again. In the meantime I’ve pursued other projects and used my time and money on those.

Cleaning, inspecting, and rebuilding it piece by piece.

Cleaning, inspecting, and rebuilding it piece by piece.

In 2017 I helped crew for my brothers race efforts on the salt flats and started feeling the itch to ride again, and I told everyone I would be back again next year with a bike. My original plans were building a brand new motorcycle in a completely different classes based on a Harley-Davidson Sportster motor. The planning, work on the frame, and everything else started immediately after getting home but I knew having it done for the 2018 race season was a tall order.

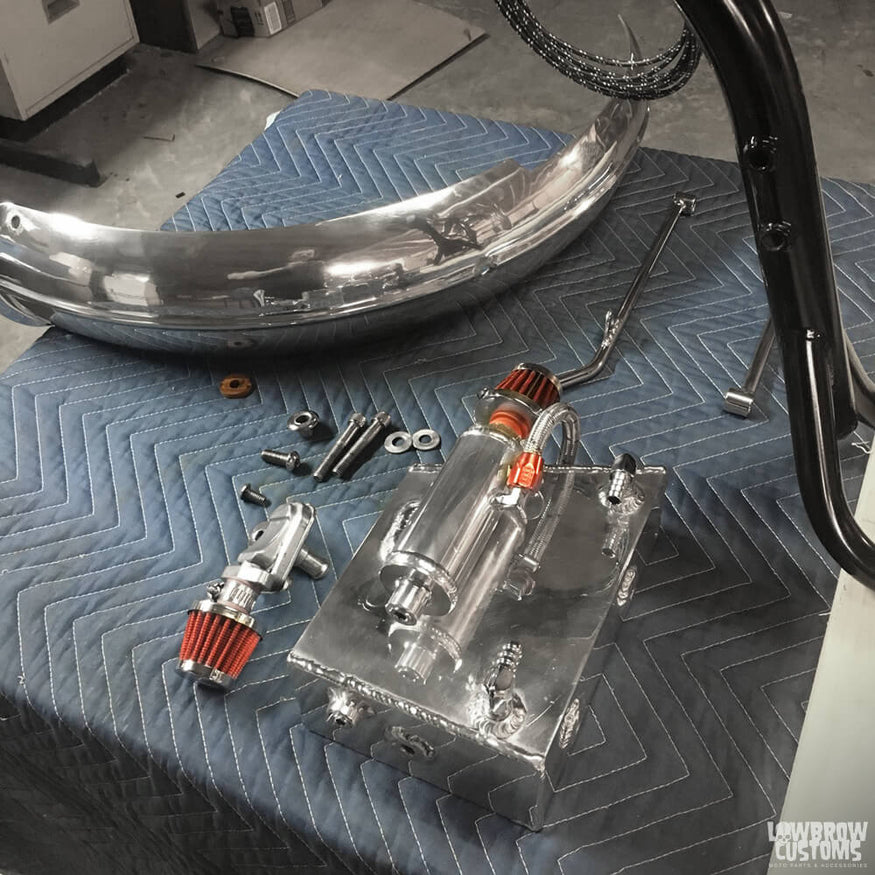

New battery setup using an Antigravity battery and Gasbox battery box.

Sometime around February my brother brought up the Triumph again. I looked up standing records, found a record I thought was attainable, and made the decision to pull it out of the mothballs. The plan started as a straight rebuild and to run it naked, without a faring or bodywork, against the 650cc A-PG special construction pushrod gas record, currently set at 130.73mph. I started a full disassembly on the motorcycle, and found extensive damage to the bottom end from the rod failure years ago, however upon inspection the rest of the chassis was in great shape.

Front end assembly and new controls.

Like most things the simple plan mushroomed into a much more complex rebuild. I tore the bike down completely, inspecting and cleaning each component as I went. I decided to change the rear wheel out to a quick change set up allowing more gearing combinations, something my previous race bikes always lacked, also adding a rear disc brake operated by a front hand control. In addition I planned an upgrade to the controls, front wheel, battery box mount, as well as several other components.

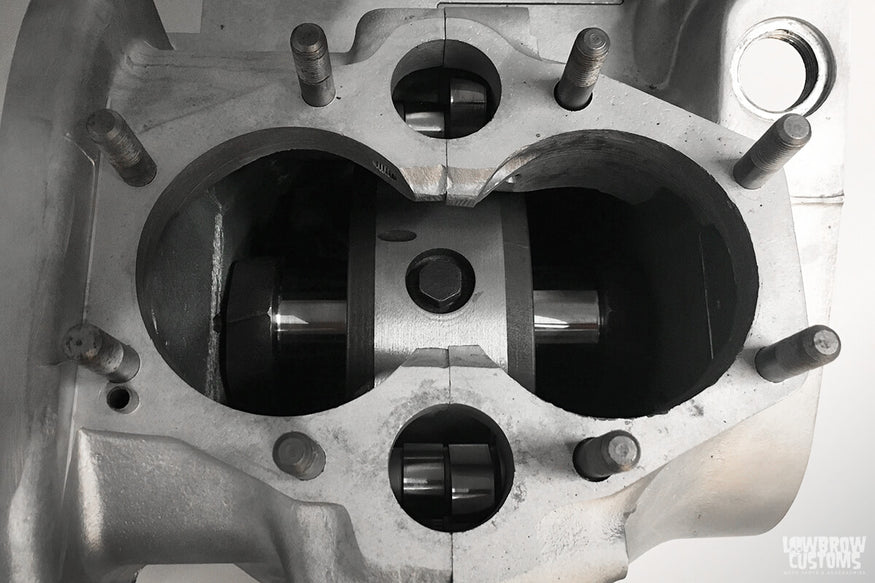

High lift camshafts hitting the crankshaft! The fix was taking .060" off the diameter of the crank.

High lift camshafts hitting the crankshaft! The fix was taking .060" off the diameter of the crank.

For the engine I had a set of vapor blasted 1966 triumph cases on the shelf in my garage that would become the basis for my new motor. I decided to go full out with this one and sent the head out for flowing and some serious improvements from previous years. I upgraded to much higher lift cams for race only application which also required clearancing of the cases, as well as machining the flywheel down.

To avoid the same issues I had in the past I switched to MAP billet connecting rods, and modern style high compression pistons. I am still running this motorcycle with a total loss electrical system, electronic ignition, and a Bob Newby belt drive. Due to the new head design I am also running modified larger bore Amal carburetors.

The high lift cams wouldn't turn, they hit the inside of the crankcases. But nothing that can't be fixed!

The high lift cams wouldn't turn, they hit the inside of the crankcases. But nothing that can't be fixed!

As I write this I have a little less than two months left to complete, and test before loading her into the trailer. I’m pretty excited for this year and to see how everything comes together on this project! Stay tuned for further updates, as I complete it I will do another post with the finished product, dyno results, and more. In addition you will be able to check this bike out in person at Fuel Cleveland July 28, 2018!

Check out Kyle's latest update in part 2 of the "Silver Bandit" 1968 Triumph Land speed build.

Test fitting the clearanced cases, new cams, and machined flywheel.

Test fitting the clearanced cases, new cams, and machined flywheel.

Words & Photos by: Kyle Malinky

Additional Photos by: Jon Glover

Final motor assembly and heading west - Bonneville!

It has been more than a few seriously hectic weeks around Lowbrow HQ. I finally received all the remaining parts I was waiting for, and began to assemble my motor for my 1968 Triumph Landspeed build "Silver Bandit". Our tech guru Todd helped with the bottom end, installing the barrel, and high compression racing pistons.

Tyler and I spent a morning in his home garage getting the racing cams degreed so that motor would be properly timed. I took the short block home to finish the build, taking the time to clay the pistons to make sure I had proper clearances. Anytime you do serious work to a motors valvetrain it is worth the extra time to make sure the motor does not grenade the first time you fire it up! After making sure everything was happy I did final motor assembly and got back to work on the chassis.

I installed front and rear wheels, making custom wheel spacers to get everything exactly where it needed to be, and installing high speed bearings. We modified the carrier on the quick change rear end to allow it to space the sprockets properly as well as the caliper for the hand operated rear disc brake.

The motor made its way home into the chassis, and I got to work installing the exhaust, gas tank, all of the controls, and wiring and plumbing the bike.

As always the first time firing a new motor is a little nerve racking, I filled the tanks with 110 octane leaded race gas, adjusted the carbs, and first kick she fired right up! The idle was a little high so after a few tweaks it was purring. I was absolutely ecstatic with how well it ran right out of the gate. I finished a few more details just in time for the Fuel Cleveland show load in the next day!

My bike looked right at home at Fuel Cleveland next to Don Miller‘s fiberglass body Triumph flat track racer, and Herb’s duel engine Norton race bike. I got a ton of great feedback and really enjoyed being part of the show! As soon as the show was done the bike came back to the shop and waited until Tuesday to dyno test it.

Murphy’s Law was in full effect, the bike was ready to run, but we had problems with dyno and only about half of every pull I completed was properly recorded. That being said we continued gaining horsepower and I planed to take my bike home do a few more adjustments and hit the Dyno again Friday.

Friday came around and we showed up ready to go, fired the bike up and hit a few great runs, tuning it in further, and gaining horse power every time. Of course Murphy reared his ugly head again and the dyno completely crashed, but the last pull I had was the highest horsepower with an extremely smooth curve. This motor came in about 8% higher than my old motor which I am thrilled with, however I know I could’ve pulled a few more horse power out if we had more time and less testing issues.

I went back to the shop Saturday for final adjustments, an oil change, some small modifications, and a good cleaning. It's crazy to think, in two days the bikes will be in the trailer and heading west. Next stop Bonneville!

Related Products