TABLE OF CONTENTS

- How I Came Up With The Idea For Lowbrow Customs

- 2004 - The First Version of the Lowbrow Customs Website

- Mid-2000’s - Starting Lowbrow In A Spare Bedroom & Garage

- 2009 - The First Employee of Lowbrow Customs

- Launching Lowbrow Customs

- Late 2000's - Passion for All Things Motorcycle

- Working With Other Motorcycle Brands & Making Friends

- Throwing Our FIrst Motorcycle Events

- Big Moves for the Small but Growing Lowbrow Customs

- Our First Warehouse in Medina, Ohio

- Lowbrow's Tight-Knit Crew and New Big Home

- 2021 Warehouse Update: We doubled our size with a big construction project!

- A recurring problem over the last 18 years... we keep running out of room!

- Keep evolving and diversifying, while keeping it real.

- Long Term View & Aggressive Goals

- At Lowbrow Customs We Eat, Sleep, Ride, Talk, Breathe, Dream, Live and Love Motorcycles

- What Turned Lowbrow From a Side-Business Into a Thriving

- We're Into What We're Into

- A Strong Focus On Things That Make Customers Happy

- Inspiring The Crew

- We Are Family Run & All of Us Here Take Pride in Doing Things Right

- New to Land Speed Racing: Knowing Nothing, Getting Ready

- Getting Motorcycle Endorsement After More Than a Decade of Riding

- Built a '68 Triumph and Did a Rookie Run

- Just Went Out There and Did It, Made It Happen

- Year Two, Went Back, and Recorded

- Core Beliefs at Lowbrow Customs

- Work Your Ass off, Put the Time In

- Learning New Skills and Pushing Continuously

- We Are Our Customers

- Curation of Motorcycle Parts & Accessories, Quality and Fit Guaranteed

- Supply Our Customers With Astounding Customer Service

- We Care

- Get to Know Your Customer, and Your Market

By Tyler Malinky

Here at Lowbrow Customs we have been supplying motorcycle parts to like minded enthusiasts worldwide since 2004. Through our entire journey, we’ve been innovating and building, creating brand new parts and accessories to supply motorcycle enthusiasts with cool motorcycle parts and accessories, getting them out onto the road. The Lowbrow Customs story: When the going gets weird, the weird turn pro.

Watch The History Of Lowbrow Customs Video

We have people mention this film to us all the time.. it clearly seems to resonate with them, and that makes us proud. Proud to have built a company that has happy employees, creates interesting and high quality parts, solves problems, and has a super vibrant following, world-wide.

This documentary-style film takes a hard look at the company's beginnings, filled with old photos, stories, and interviews from Tyler Malinky, founder and CEO of Lowbrow Customs, his brother Kyle Malinky and the rest of the staff. Sit back, grab some popcorn and take a ride with us here at Lowbrow Customs.

How I Came Up With The Idea For Lowbrow Customs

2004 - The First Version of the Lowbrow Customs Website

Back in the early 2000’s I was riding my 1970 Triumph, my first motorcycle, and learning to work on it. I rebuilt the top end of the engine, and later rebuilt the entire engine and customized the bike.

Through all of this I was trying to find parts and information on vintage motorcycles and choppers with limited success. I often would finally order motorcycle parts and not be happy with what I received, if it ever showed up.

I decided that I could do starting a motorcycle shop and registered the lowbrowcustoms.com domain name and drew the logo. Fast forward a year later and I still hadn’t actually done anything with it, but in 2004 I started off by making a simple website which I coded page-by-page in HTML, with Paypal ‘add to cart’ buttons.

- This is the Lowbrow Customs website back in 2005. Way back then this website was considered quite good!

Mid-2000’s - Starting Lowbrow In A Spare Bedroom & Garage

At the time I was a self-employed sign maker, doing graphic design for customers, simple web design, screen printing and lettering work vans, shop windows, making banners and anything else with lettering on it. I used my sign-making equipment and skills to make various motorcycle and counter-culture stickers and a few t-shirts, in addition to finding some of the various chopper underground magazines, like DiCE Magazine.

I started carrying DiCE Magazine around issue #3, and early Lowbrow ads can be seen starting around issue #5 or so. This all happened out of a spare bedroom of a duplex in Parma, Ohio. It then expanded to also take up part of my basement.

Back in the early and mid-2000’s there weren’t many motorcycle shows to speak of. Not of the vintage chopper variety at least, and not around northeast Ohio. I would load up my 1965 Econoline van (that I had painted flat black with a roller and a gallon of Rustoleum) with a small folding table, a Lowbrow banner and my wares and would head out to small hot rod shows around the Midwest.

2009 - The First Employee of Lowbrow Customs

- My brother Kyle helping work on my 1970 Triumph in the basement of my house in Parma, circa 2002. Kyle started working for Lowbrow in 2009 and helped grow and build the business over the years.

- My brother Kyle helping work on my 1970 Triumph in the basement of my house in Parma, circa 2002. Kyle started working for Lowbrow in 2009 and helped grow and build the business over the years.

The first 5 years of Lowbrow I was the only employee and worked evenings and weekends on top of my normal full-time job as a sign maker. Things changed when Kyle, my brother and current President at Lowbrow Customs, moved back from the west coast. I told him I was having success with Lowbrow on a small scale but I really wanted to make a go of it and try and do it full time.

I couldn’t pay him much but asked him to commit for a year to see what would happen. His skills balance mine out well and together we are a good team. Since about 2007 Lowbrow had been operating out of the large garage out back of my house in Hinckley, Ohio. It was a converted garage that we dry walled and finished off with heat in each bay.

- Here I am hard at work in the Lowbrow Customs office, circa 2009.

- Ye olde Lowbrow garage behind my house, home to Lowbrow Customs 2007-2012.

- Ye olde Lowbrow garage behind my house, home to Lowbrow Customs 2007-2012.

- Kyle packing some orders up to ship out. Through the door is the small bike workshop, and beyond that the office.

Launching Lowbrow Customs

Late 2000's - Passion for All Things Motorcycle

We started expanding the parts end of the business, going to more shows, working on our own bikes and starting to work on our first land speed racing bikes with the intent of making it out to Bonneville on vintage Triumphs. Our combined focus helped grow Lowbrow as more and more people started to hear of us via word-of-mouth and ads in mostly underground motorcycle culture magazines and online forums.

- DiCE Magazine, Biltwell helmets, Lowbrow t-shirts and various other items on the shelves back in the late 2000's

- DiCE Magazine, Biltwell helmets, Lowbrow t-shirts and various other items on the shelves back in the late 2000's

Lots of orders being loaded up into Kyle's wagon for the ride down to the local post office.

Lots of orders being loaded up into Kyle's wagon for the ride down to the local post office.

Working With Other Motorcycle Brands & Making Friends

I did the El Diablo Run with my friend Greg back in 2008 (me on a rigid ’74 Honda CB750 chopper, and Greg on his wild Yamaha XS650 chopper) and became friends with the guys at Biltwell.

Lowbrow already carried Biltwell helmets and the few parts they had at the time, and as we continued to advertise and sell their products we became one of their US distributors. Kyle and I would package orders as they came in and load them in our personal vehicles and drive down the road to the post office to drop them off each day.

- The bike workshop. The Triumph on the lift ends up becoming Poison Ivy, my first record-holding Bonneville land speed race bike.

- The bike workshop. The Triumph on the lift ends up becoming Poison Ivy, my first record-holding Bonneville land speed race bike.

- Checking out the riding position on Poison Ivy on the driveway outside the garage. This seems like a lifetime ago.

- Checking out the riding position on Poison Ivy on the driveway outside the garage. This seems like a lifetime ago.

- Poison Ivy at Bonneville Speed Week in 2010. Qualified for a land speed record that year but I bent an exhaust valve on the return run. I went back in 2011 and set 2 records. Photo: Michael Van Parys

- Poison Ivy at Bonneville Speed Week in 2010. Qualified for a land speed record that year but I bent an exhaust valve on the return run. I went back in 2011 and set 2 records. Photo: Michael Van Parys

- Kyle's Triumph race bike at Bonneville Speed Week 2010. He assembled this bike in the Lowbrow office, behind my chair. No records in 2010, however he broke two in 2011. Photo: Jon Glover

- Kyle's Triumph race bike at Bonneville Speed Week 2010. He assembled this bike in the Lowbrow office, behind my chair. No records in 2010, however he broke two in 2011. Photo: Jon Glover

- My 1959 Panhead chopper in progress around 2011. I finished it that year.

- My 1959 Panhead chopper in progress around 2011. I finished it that year.

- My 1959 Harley-Davidson Panhead chopper outside of Lowbrow Customs HQ in 2017.

- My 1959 Harley-Davidson Panhead chopper outside of Lowbrow Customs HQ in 2017.Throwing Our FIrst Motorcycle Events

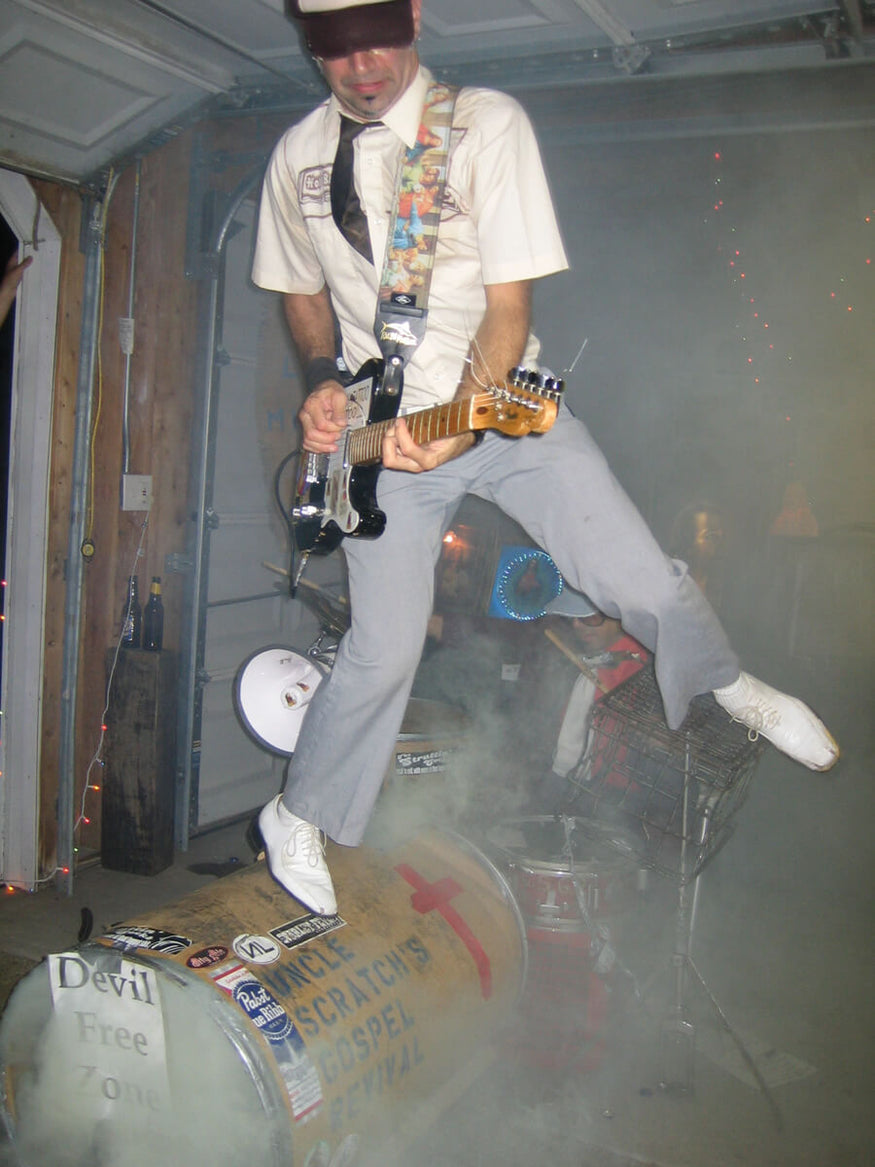

- 2008 - The Lowbrow Beer Brawl: the first one was there in my backyard in 2008 and was called The Lowbrow Beer Brawl. About fifty people came out for it and we had a great time, with a huge bonfire in the yard, Uncle Scratch’s Gospel Revival playing in the garage, bikes and hot rods all over the place.

- 2010 - The Lowbrow Getdown: We also started The Lowbrow Getdown in July 2010, creating a killer annual campout at Nelson’s Ledges Quarry, which is still going strong today. During this time we hired Katy, who is now our VP of Operations. Towards the end of operating out of the garage we even had a bathroom built in! When it got to the point that we were considering putting shelving in the bathroom we realized we needed more space.

- Hot rods at the first-ever Lowbrow party, the Lowbrow Backyard Beer Brawl, which was held in my back yard in 2008.

- Hot rods at the first-ever Lowbrow party, the Lowbrow Backyard Beer Brawl, which was held in my back yard in 2008.

- A couple cool Triumphs in attendance, ready to party.

- A couple cool Triumphs in attendance, ready to party.

- Uncle Scratch's Gospel Revival put on a crowd-pleasing show.

- Uncle Scratch's Gospel Revival put on a crowd-pleasing show.

- In addition to burning a giant wood robot full of fireworks we also burned a piano.

Big Moves for the Small but Growing Lowbrow Customs

We also started to get customers showing up from other countries out of the blue. Apparently they thought we were a larger motorcycle parts company in Ohio and they were not expecting the address to take them to a building behind some small house out in the country, next to an apple orchard.

In one day we had customers showing up from both Spain and Japan. This was another sign that we needed to move to more official headquarters, instead of operating a business illegally out of a home garage!

Our First Warehouse in Medina, Ohio

Once realizing we needed more room I started looking for a bigger building to lease or to buy. We looked at different places for lease which were essentially big boxes with a roll up door at the end, none very appealing.

We ended up finding an 11,000 sq ft warehouse for sale on 22 acres of industrial land in Medina, Ohio for cheap. The owner had bought it at an auction 6 months prior and was flipping it having done no improvements or work on it. The warehouse used to be a truck service building for a large local construction company that had gone bankrupt, and had sat empty the last few years.

I got a great deal on it and even got a bank to give me a loan, which was a big move for our small but growing company. We cleaned the warehouse and cleaned up the lot around it and moved everything in over the course of a weekend.

- It's a beaut, Clark. Lowbrow Customs' home in Medina, Ohio. Everyone loved that tenth mile long, loose gravel driveway. More than one rider ran out of talent on our driveway and ate it!

- It's a beaut, Clark. Lowbrow Customs' home in Medina, Ohio. Everyone loved that tenth mile long, loose gravel driveway. More than one rider ran out of talent on our driveway and ate it!

- The warehouse sat on 22 acres of industrial land, which was old farm land. Little Red, aka 'the donkey trailer', has been a faithful motorcycle hauler for many years.

- The warehouse sat on 22 acres of industrial land, which was old farm land. Little Red, aka 'the donkey trailer', has been a faithful motorcycle hauler for many years.

- Double Vision, my dual-engine 1955 Triumph land speed motorcycle which went on to break three land speed records at Bonneville Speed Week. This is the first time the bike had been off the lift. After Lowbrow moved to the warehouse the garage became my bike workshop.

When we moved into the new building is when I hired my long time motorcycle friend, Todd Muller, who is our Head Motorcycle Tech here at Lowbrow and whom many of you know from appearances in Lowbrow how-to technical and part install videos.

Back then I thought we had so much room and we would skateboard around the warehouse and enjoy our giant R&D and motorcycle work area, complete with four lifts and all the necessary tools and equipment.

Everyone had a bike or two there to work on, and sometimes at lunch time we would go ride dirt bikes around the property, as it was lightly wooded and hilly, with no neighbors anywhere nearby. That location worked well for us, lots of room and no one could find us, which we liked because we didn’t have customer pick-up or a showroom.

We shipped all our orders out and worked on designing new products and finding cool motorcycle parts and accessories all around the world and stocking them on the shelves there at our shop.

- The main bay stocked full of parts, helmets and motorcycle goodness.

- The main bay stocked full of parts, helmets and motorcycle goodness.

- The 'middle bay' which started as an R&D and bike work area, but slowly got overtaken by shelving.

- The 'middle bay' which started as an R&D and bike work area, but slowly got overtaken by shelving.

- The screen printing operation long ago, before the automatic press was moved in and installed!

- The screen printing operation long ago, before the automatic press was moved in and installed!

- Katy on her dirt bike for a lunch time or after work ride on the property.

Lowbrow's Tight-Knit Crew and New Big Home

A few years later and our motorcycle parts company in Ohio had grown, having added more Lowbrow team members to help respond to questions, ship orders, handle graphic design, and all the other tasks at hand. It was time to look at moving again as we were running out of space at the warehouse.

The big R&D area had been pared down to only a single motorcycle lift long ago, as the room was needed for shelving for motorcycle parts, helmets, and riding gear. I was on the search and we ended up at our current spot in Brunswick just twenty minutes south of Cleveland, Ohio.

We own this building, and having built it out to suit us I don’t expect to ever move again, we have found our home.

- Lowbrow Customs headquarters getting dialed in before we settled in, February 2016.

- Lowbrow Customs headquarters getting dialed in before we settled in, February 2016.

- Added a second floor above the existing showroom / break room.

- The completed Lowbrow HQ circa 2017. It didn't really hit me how amazing this building and move was until they installed the sign and I saw it lit up at night. Legit!

- The completed Lowbrow HQ circa 2017. It didn't really hit me how amazing this building and move was until they installed the sign and I saw it lit up at night. Legit!

2021 Warehouse Update: We doubled our size with a big construction project!

A recurring problem over the last 18 years... we keep running out of room!

When we moved into our warehouse in 2016 I would never have dreamt that we would need to add on to the building just five years later... And not only add on, but double the size of our existing building!

Here the grading has been completed, as well as footers, and everything is getting prepared for the arrival of the steel building components.

My only experience with what I would consider large construction was the renovation of our warehouse when I first bought it. This expansion project was a learning experience for me, from dealing with the city planning commission and obtaining permits, to securing a loan so we could gain the space we desperately needed.

After a few months of what seemed like slow progress, the steel girders and decking went up in a week. It seemed like all of a sudden our building was truly under construction!

The entire project went very smooth, with just problems that are common in 2021... Shortages and delays! Oh, and everything was more expensive, too, lol! So there's that. The addition is now finished as I write this, on December 7th, 2021, except that we are waiting on some more glass for the windows (hence the plywood), and the pallet racking we ordered four months ago won't be in for another 2.

Once the roof decking was in place, electricians and HVAC went nuts running all the power and high-bay LED lights, as well as gas lines and tube heaters.

The extra space will allow us to continue to expand our offerings, supplying some of the highest quality and unique motorcycle parts that there are, world-wide, to all of you! I can't even imagine what the update might be another five years from now... Whatever it is, I think it will be another fun one!

The addition melds nicely with our existing building... Already I can't believe we only had a small square building, it seems so natural to me now even though we just started using the full expanse! Final details are still getting wrapped up, including some windows, paving and striping of the lot.

It's a beaut, Clark! Check it out! Never again will this building be so shiny, clean and dust-free! The calm before the storm...

Even though our entire building is free-span, we left the internal divider wall up as it will have pallet racking on both sides anyhow. You can see the pass-throughs to the original half of the building, with each end passageway large enough for a tow motor and other large items.

Keep evolving and diversifying, while keeping it real.

Long Term View & Aggressive Goals

We are right near the highway, have a huge parking lot where we host our free Lowbrow Swap & Meets, a killer showroom for customers to check out parts and pick up orders, and more room than necessary (currently) for all the parts, helmets and gear that we stock here at Lowbrow. Our warehouse used to be owned by a bingo company and was used to store pallets of paper bingo cards.

Now it is home to the entire Lowbrow team, working on new parts for your bikes, shipping out orders, planning events (such as Fuel Cleveland) and producing tech articles and videos. Since the story of how it all got started, I love this company and am passionate about what we do. I started Lowbrow to create a motorcycle parts company and run it how I think all business should be run, doing the right thing, caring about what will be happening twenty years from now, not just next month. I am excited to see what comes next!

- The crew that makes it all happen. These are the people who genuinely care about taking care of you and making sure you have an amazing experience.

At Lowbrow Customs We Eat, Sleep, Ride, Talk, Breathe, Dream, Live and Love Motorcycles

- Lowbrow official headquarter

We take pride in what we do, stocking thousands of motorcycle parts in house so our tight knit crew can make sure your orders get out the door and into your hands quickly. We actually know how to use the parts that we sell and if you need help we are here for you. We are our own customers, that makes it easy for us to design and innovate the parts you need for the road ahead. Above all else... WE RIDE.

If you read this far then thank you. It is people like you who help make this a reality. Thank you for your support of our little world.

Lowbrow Team and the Company History

Backstory and Connection to Motorcycles

Tyler Malinky: When Kyle and I were young, our mother in particular didn't want us riding motorized vehicles. I mean like no mini bikes, or three wheelers.

Kyle Malinky: No. Yes.

Tyler: Anything like that.

Kyle: Go karts. [laughs]

Tyler: Nothing. Of course we did like over friends houses and that kind of stuff. We'll get hurt occasionally and not tell my mother how I think I broke my ankle, that kind of stuff.

Sharon Zahtilla: They were very, very energized when they were young. They did not sit around, which they still don't. [chuckles]

Tyler: Anyway fast forward, I know I was 18, I didn't know anything about motorcycles, I didn't know anything about mechanics. I was really into computers and graphic design, and for some reason I just really like the look of vintage triumph Motorcycles. I ended up buying a 1970 triumph with a 1978, 750 CC, five-speed motor in it that was an old flat track race bike. I think you went to pick that up with me, didn't you?

Kyle: Think so, yes.

Tyler: I remember where I bought it, it's somewhere in Ohio. Really cool bike. I lived in Parma, Ohio at the time, and I literally learned to ride by bump starting it down the driveway right onto State Road into traffic having no idea really what I was doing, and riding it around and just figuring it out basically. That's how I got into motorcycles.

I started Lowbrow in early 2004. I worked full-time in addition to Lowbrow for the first five years as a graphic designer and a sign maker. Until Lowbrow gradually became more and more of my day and I decided to go for it essentially. I would do graphic design and a little bit of website design, HTML programming, and doing lettering work vans and banners, and basically lettering on it.

I was self-employed, I just did that out of my house. I had that bike and I was working on it. I didn't know how to hardly turn a wrench when I bought it. I was trying to find parts and information back in '04. It's hard to remember now, but it's not like there was a bunch of places to buy motorcycle parts at all online, not many. Especially not for vintage motorcycles and now for choppers.

Hard Look at the Company's Beginnings

- Tyler and Kyle at Lowbrow official Warehouse

Kyle: Such an early time in the internet age people forget, you couldn't go out on a thousand forums and look at all this stuff. That exposure was a lot more limited than it is now.

Tyler: I was trying to find parts for these old triumphs. I didn't know anyone locally, I was just learning how to do anything mechanical. Like say ordering parts was hard, finding the parts. Then, "Would they ever show up? Are they going to be what I need?" It was really a painful experience. Painful meaning, just a total pain in the ass. I thought, "Shoot I could do better than this." That's basically how Lowbrow started.

The name I just made up and I thought it sounded good, I guess. I don't remember, I thought it was a good name and I still do. Bought the domain name and design the logo. This was probably in '03, and I proceeded to do nothing with it for a solid year or something. Then one day I just got my butt in gear and said, "All right, I'm going to make a website," and start trying to make this happen.

I started with using my sign making equipment and abilities, doing stickers, printing t-shirts, carrying dice magazine around issue four, or something. Just starting to get in like hard to find an underground media. That was when no one knew any of these things basically. It was hard to find, you couldn't even find it in the United States mostly. Going to a lot a little Hot Rod Shows. There weren't really many motorcycles shows around that weren't your run-of-the-mill like poker runs and things like that.

Anyways, slow like I'd go and set up at a show with a four foot card table and like a few motorcycle t-shirts and a few magazines. I'd sit there and talk to people and sell a few things. At the time I was driving a 65 Ford Econoline that I had painted with a roller Rustoleum flat black. It had holes through the floor and it was a total junker. A lot of time, a lot of effort going to tons of shows, and just earning customers one at a time. Getting people to know who we were, trying to get people to the website and that kind of stuff. Lowbrow started growing and I moved from the bedroom upstairs to the basement, and then was using the bedroom and the basement.

Jason Longhair: He was helping me build a website for myself. I remember going to his old house, and it's just boxes stacked up everywhere. I'm like, "What is all that?" He's like, "That's just Lowbrow stuff. Those are orders I have to ship out. I'm like, "Wow, people really are buying this."

Tyler: That went on for a couple years and I was really running out of room, and ended up moving to the country, to Hinkley, Ohio, where I ended up with a house that I bought at auction cheap, with a flooded basement and no kitchen. The house is gutted and all this. It was an 800 and some square foot house and 2,000 square foot garage. I bought that house because of the garage, that's like all I cared about.

That was a new home of Step Above Signs, my old sign company and Lowbrow Customs for the following five years or so. Still just myself, doing everything, posting things on forums, working on bikes myself. Riding bikes, doing things like little events like going on the first gypsy runs that Walter was putting on out on the East Coast. Basically any events we could find. At that point we weren't putting on- or I wasn't putting on any of our own events yet.

We started sharing more parts, having some small different parts made. I would design some real basic parts and have them made by local machine shops and things. We started carrying Biltwell, helmets, and handle bars and things when it was the first or second year in business, and selling those which were getting really popular. Not nearly as popular as they are now, but it was the budding vintage style chopper movement.

Around 2009, maybe, 2008, my brother Kyle moved back from I think San Diego maybe, at that time West Coast somewhere. He moved back and I was getting too busy to do the sign company and Lowbrow and I like doing low brow so much more, and I had that feeling like, "This is the time to really just like go for it." What's the path? What's the point of this? What do I want to do with it?"

I remember telling Kyle like, "Hey, I think we could do something with Lowbrow. I think this could be something, but I can't really pay you much money because I don't have very much money." I think I talked about $8 an hour.

Kyle: I think so, yes.

Tyler: I said, "Work with me for a year, and if it works out and I think it will, it's going to be great. If it doesn't it's like no harm no foul," whatever. We try and we-- That is what it is.

Kyle: It was actually a combination, it was Lowbrow and the sign company. It was like whatever needed to be right.

Launching Lowbrow Customs

Launching the Business

Tyler: Whatever filled the days and when Kyle came on board, we really work well together. I'm great with ideas, he's very good with execution and organization. He was my first employee there behind the house in Hinckley. That year things really just started exploding growth-wise, really just started carrying a lot more perks, getting a lot more customers, selling a lot more products.

People started, I guess knowing about us. Finding the website. People started showing up at my house I think thinking it was going to be a store. We also hired Katie, who's still here, while we were behind the house. Once I had Daly, my first daughter, really it was time to move because we didn't have a bathroom in the shop at the time. I would tell Kyle like, "No, you're not going in the house the baby's sleeping," and he'd have to drive to the gas station to use the bathroom. Things like that.

I remember when one day we had a couple shop from Tokyo at the garage door. They just were like in town, I think drove from like Chicago, which is six or seven hours away without calling at or anything. Then that same day two guys showed up from Spain, and I thought, "Okay, this is ridiculous we need to move out of my backyard."

Jason Longhair: He was like, "I'm closing down the sign business. Lowbrow's actually doing good." We were all blown away, I know I was.

Tyler: That's when I started looking around and ended up buying a big chunk of industrial land in Medina, Ohio 22, acres with a really crappy old warehouse on it, sat way back that you couldn't see from the road. Got a heck of a deal on it that had been empty for a number of years the industrial land was pretty much like brambly woods.

Todd Muller: Tyler being the awesome boss that he, is we had dirt bikes. He actually hired a guy to come in there and run through the woods with a bobcat to make some dirt bike. Just randomly and during the middle of the day when we're supposed to be working, we'd get a dirt bike and go for a ride out in the field. He goes, "It makes the workers happy when they can do something fun and then get back to work."

Tyler: It was very private. I had like 10-mile long gravel driveway with big ankle break sized chunks of gravel.

Kyle: It's about the worst motorcycle company driveway in the world.

Tyler: Right. It was like that's where it tested people's talent, because a lot of people wiped out in that driveway. You're going slow and if you don't know how to ride in loose huge gravel-- We're in this warehouse, old truck service warehouse. It was great. It was 11,000 square feet, so going from our old shop to that one, we were skateboarding inside.

Kyle: Rocker bike and motorcycles and dirt bikes through it.

Lowbrow Team

Tyler: We had so much room for a tiny bit of time. We kept growing, we started hiring more people. Todd Muller, our Head Motorcycle Tech, who is one of my good friends, and I've known him for years via Vintage Triumph. Kept asking, because he wanted to work at Lowbrow for a number of years and I just felt like, "Man, I can't even afford another employee. At some point we'll get there." When we move to Medina, it was right at the same time as when I had Todd.

Todd Muller: Well, basically in the early days of Lowbrow it was just Tyler in his garage behind his house. I'd call over there and no one ever answered the phone. I used to leave silly phone messages saying, "I'm calling about the job, answering the phones." Just goofing around. Now here I am, several years later, answering the phones talking to customers.

Tyler: He's a real character, super solid guy and has been working on motorcycles since before I was born. He's full of knowledge and a super important part of Lowbrow, our team, our brand, our information that we get out there, our customers and stuff for free. We just started hiring more people at that point. We went from three to-- I don't even know when we left, probably 10 or 11.

Kyle: I think so because we got Jim Dove, who's now our warehouse manager, was hired on then.

Jim Dove: I applied and immediately got a callback from Greg, gorgeous Greg everybody knows him. He's like, "Hey man, you want to come over man? Please come on down, man." I'm like, "When?" He's like, "Now man. We're here." I'm like, "Okay."

Kyle: Toni Record, who's basically our head customer service, he was hired.

Tony Reichert: All of a sudden got a call from the buddy I worked here, "Hey, on this job opening, this Lowbrow Customs place, it's cool a motorcycle shop." I'm like, "Yes, cool. Sounds great." I walk in, I see Tyler and Kyle sitting at the desk just neck down covered in tattoos and I was like, "Well, that's great."

Kyle: Troy who does programming-- [crosstalk] He was long hair.

Tyler: Jason, who's our graphic designer.

Jason Longhair: Me and Tyler are high school friends. There was always a joke like, "Oh, one day we're going to work for you." He didn't really want employees. I lost my job, I'm like, "Hey man, can I use you for references?" It was like, "No, come in let's talk." We started talking and here I am six years later working at Lowbrow, kind of surreal if you ask me.

Growth of the Business

Tyler: In the three years maybe, we were in Medina. The company grew, honestly so quick like I didn't ever have time to think about it because we were basically just jamming all the time. Also always by the seat of our pants.

Kyle: By the time we moved we had four shipping containers in the parking lot full of stock because the building was too full. We had six people in an office the size of this room.

Tyler: All guys, it was horrible.

[laughter]

Kyle: We just hit capacity, we were way past capacity.

Tyler: Yes. It would rain and there was like 200 leaks in the roof, literally.

Kyle: We always joke about how much the building leaked, every time it rained outside, it rained inside because there were so many screw holes in the roof. It was kind of ridiculous, I'm going for years trying to fix all those leaks.

Tyler: It just was not an ideal building, so we ended up selling that and buying the warehouse we're now, which is in Brunswick. It was a bingo-card-warehouse, it was literally full of bingo cards, palletized bingo cards. We ended up borrowing every dollar I could get to buy that building. We have a really nice showroom that's open to the public, Monday through Friday. Customers land from too far away, come by pick up their parts.

We pull things from the shelves so they can ride their bike up and we can grab handlebars, they can hold them and sit on their bike and check stuff out in person. We also get people stopping by who are riding or driving cross country, who pop in just to check Lowbrow, which is pretty neat. Hopefully, we will never have to move again because it was a total pain, I spent every dollar I could borrow to be here and I'm glad I did. I couldn't be happier with our setup now.

What Turned Lowbrow From a Side-Business Into a Thriving

We're Into What We're Into

Tyler: The way I run my business and this would go for myself personally, for employees, also how we treat our customers and deal with our customers. It's the same way I live my life. It's super easy if you do it. It's basically, I don't lie, I don't rip people off, I'm always trying to do things that are win-win, what's good for me and good for other people. I find that if you're honest, you're authentic, you're true to yourself, and that's what you share with people, then life's really fricking easy.

We look at business from the viewpoint of a customer like, "I'm the customer, what's the best-case scenario? What's going to fricking wow me and make me stoked to do business with this company?" That's how we still operate and say, "Well, I want the coolest stuff that fits perfect, I'm going to have all the information I need before I buy. It's going to ship right away and if I have a question I can call and I can get help with it." We just trying to do everything that we want as customers and then it makes things really easy because if you're looking out for your customers and not just for your bank account or yourself, then naturally I think business follows.

Jim: With the customer service, like the power that he gives me to, like take care of these people. How, "If that was you, how would you feel if this happened?" He's the owner of the company but he's one of us kind of thing. He knows like, "Oh, that's not a good situation that it happened like this. What can we do to make this better? Let's try to help this out." That's how he would want to do it or things like that so yes, it's cool.

Tyler: We have lots of like vibrant base of customers and enthusiasts, and people who support us in more ways than just being a paint customer but meaning, people who are down for the cause. We're into in what we're into.

A Strong Focus On Things That Make Customers Happy

Mike: I think a big misconception is, people think we're a huge company, but there's only 12 of us, and that's including Tyler and Kyle.

Tyler: Mike, he mentioned that some forum, some guy posted that we're some big corporation and we're ripping people off. People just piled on in our support saying, "What the heck are you talking about?" I love that because we don't need to worry about refuting the odd naysayer because there's nothing to refute. I think people are so used to getting screwed honestly by businesses that people get blown away.

If we have someone who has a sub par experience, or whatever it's our fault, or it's a shipping problem, or whatever, we take care of them. Man, that's something that, like you get someone who's pissed and then they're expecting to get screwed, then you make it right. We spend money to make that customer happy, whether it's shipping out a replacement part, or overnighting it, or whatever.

It changes their attitude because they're so ready to get screwed over, that it almost kind of shocks them. Those people often tend to be our biggest ambassadors, enthusiasts. They're the one out there who's then telling everyone how we stand up and did a good job. The way I look at it, we throw a big camp out like the Lowbrow get down, we're drinking beer and sleeping in the dirt with guys camping out, swimming in the quarry, riding motorcycles.

Well, of course, they're going to do business with us, why wouldn't they want to? We're developing those relationships that are real relationships, the camaraderie, having a good time. You have a good time with someone you trust them. When it's authentic and it's legit it's super easy. I think people who have trouble in many industries, but even like in motorcycling for sure because they're posturing.

Kyle: Trying to manufacture an image.

Inspiring The Crew

Tyler: Right, yes. "I'm not a tough guy, don't fuck with me." [laughs] I not kidding, I look like a tough guy, I like that fun, I ride motorcycles with a smile. It's a good time, I think that's the reality of it for people. I think just being real. I didn't know how to do anything on a motorcycle when I first started riding, everyone starts somewhere, and being honest about that stuff it's just real. It's regular where the machismo, the bravado it's like, I think it's ridiculous.

I think it's like so transparent, absurd and simply by not doing that, just being real, you know if someone's full of shit or if they're authentic. That's kind of it in a nutshell. It's like if we do what's right and what's right is standing behind our products, providing cool parts, designing great new products, we don't spend a bunch of money on advertising or things like that, but we spend a lot of money on making our customers happy.

It's easy to know what parts to make, or what to do, or how to reach out to people who might be interested in what we do because it's that's what we're interested in. I don't know, it's just natural. We're in the motorcycle business because we love motorcycles, we're not in the motorcycle business just to make money. It's more than that. It's a passion. It's a creative outlet.

I feel like I know I love what I do and I love that we built this. To me, business it's building your own world, so no one would give either one of us this job, you know what I mean? Like it just isn't happening, so we had to make the job. We make the company that we would want to work for, and hire the people we want to work with, do business the way we want to do business, and now it's all on our terms, to me, the way our businesses should be running.

Jim: He wants to make sure that you're having a good work experience, he knows that this is a job. [laughs] One thing is, there's not really a turnover rate here because when people come here they love working here so much that nobody leaves.

Mikey Revolt: It's been and really inspirational to see how he does things, and to see how it trickles down into the whole staff. Then also how it translates into what we do as a business. He doesn't see it as a business. It's a hobby, it's a fun thing. He treats everyone with respect and equally, and we all have fun together. To see it as not just a business, but an organization of fun and creating.

It's brilliant to see the stuff that he puts out and drive that he does to create parts to be innovative and above everyone else in this industry. It's pretty special also to be a part of. I feel proud to come to work every day and help create his vision and my own vision. That's the other thing. He always pushes everyone to have their own vision, but as long as it's a united front in certain aspects. It's really cool to see that he's very supportive in that.

Todd: He's very down to earth. He treats everyone here at the shop with respect and kindness, because of the fact that we were friends before I started working here. He almost didn't give me a job working here because he said, he goes, "Todd, I'd like to give you a job working for me. I think we could use you but I'm a little concerned because we're friends. I don't want to lose our friendship because the new job doesn't work out for you." He's just a really super nice guy. There's nothing you can find that you don't like about him. It's the fucking truth. You can ask anybody about Tyler. He's modest too.

Tony: He goes above and beyond for all of us as employees and just friends too. That's cool. Your boss is a friend, and then you feel comfortable and you can talk to him and not feel we're going to the boss.

Kaitie Rosiu: What Tyler does for us is super awesome. I've never had a boss that goes out of his way and actually notices that you're working hard and actually appreciating it. It's very family oriented here. That's what I love most about it because it's like, not only did I get a cool new job, I gained a family. I think that's the best thing about it.

Jason: It's just like working for a family. Obviously, Tyler and Kyle being brothers, we all have our own quirks. We all have our own way of doing things, but it all seems to work.

Kyle: Yes, Tyler is CEO. That means my brother is the boss. Most of the time we are on the same page. We're still brothers, so here and there that kind of gets pulled into disagreements, and it can be pretty funny.

We Are Family Run & All of Us Here Take Pride in Doing Things Right

Sharon: It's the culture. It's from the up-down. I have to say that I'm just really impressed that I raised such wonderful young men and that they're taking care of their individual families because they each have their own family, and that they take care of Lowbrow like a family.

Todd: The majority of employees that are here have been here from the beginning. We've seen a couple of people come and go that went for other opportunities, but a lot of the people that are here today were here when the business got its initial start in the first warehouse.

Tyler: I don't want to, for instance, be some old guy with a bunch of money. That wouldn't make me happy, what makes me happier saying, "Hey, I'm going to provide jobs. I'm going to provide people with the opportunity to make good money and have a lot of perks and benefits." We do everything we can to go beyond the average. Basically, it's like, we want to take care of everyone because these people all around me are my friends, and some of them are my family. When the company does well, everyone here does better. Years from now, I want everyone to be really excited that we've all been working together and had that opportunity.

Todd: I was reading a silly Easy Rider magazine. I saw an advertisement for a Harley Motorcycle School. I said to my wife, I said, "Gee, I like working on bikes. Maybe I should go to this school." Shortly thereafter I was enrolled in MMI. I was supposed to go to school in Florida, but my 46 Chevy truck was not going to Florida. We only made it as far as Arizona. I basically called the school from a campground outside of someplace in Arizona and said, "Hey, can I go to school in Arizona?" They said, "Sure, no problem."

I graduated from Harley School. I believe it was right around 1990. I went to work at a shop and I was like, "Holy crap. I get to work on bikes all day, and I get paid for this and then I get to go for a ride. This is the best job ever. I love this job." After many years of doing that job, I was getting kind of burned out on working on Modern Harley. I wanted to stay in the motorcycle business and that's why I came to work at Lowbrow.

Jason: My main hobbies are really just going to concerts and following Metallica around. I'm at like almost 60 sometimes seeing them so far. I have like 14 more on the books for this upcoming 2019 year. Lowbrow has been pretty positive as far as giving me the go-ahead, "Go. It's your dream, go do it. It really is a dream. Just to go follow them around. That's my number one hobby, expenditure and all the above.

Jim: I do murder mysteries, I do stand-up comedy. I haven't done a stand-up comedy in a while, but it's really hard. The last time I did a stand-up comedy show, a legit stand-up comedy show says the truth. Friday Night, I killed. I did like half an hour. Everybody loved it. Guy was like, "We want you to come back tomorrow. You're the opener. You're the head guy. You're going to be the main guy because the main guy can't so it's you the main guy."

Like, "Great. It's like you'll get $75." I'm like, "I need that $75. That's sweet." I go in, the same set I did Friday. I come in and in the first 10 minutes, zero laughter and this is all I heard. I heard ice on a glass and someone go. I was like, "Thanks to everybody." I'm like because if they weren't laughing at the first 10 minutes, they're not going to because the first 10 minutes was heavy.

It was heating the night before. Stand-up comedy is tough. I have bombed before but that was probably the hardest. I did comedy at a laundromat and it went over better. This club, so I haven't done stand-up in a while but I do that. I'm an entertainer. I do murder mysteries, stand-up comedy, sketch comedy, anything that entertain. I love doing that.

Mikey: I used to be in bands and used to do art a lot when I was in high school and out of high school. I toured the country with bands when I could. After my mom died, I lost everything. My ways of anything artistically and photography just fell into my lap really two, three months on a bender of just drinking nonstop. My wife's like, "You need to get your shit together."

After realizing how much of a sheep I was, I was like, "I need to start creating again." I started painting and it wasn't really gratifying. I saw our camera sitting there just collecting dust on our shelf. I said, "Hey, what's this doing here? Can I use this?" Like, "Yes, go ahead just don't break it." I've never looked back since I touched that camera. Just being able to take it to different parties and get that instant gratification of shooting something.

Going to a motorcycle show or a car show and shooting stuff. Then coming home and instantly seeing what I looked at in a visual eye. Then editing and tweaking and creating something beautiful. It was like night and day for me and just nonstop from there on out. Then the video aspect of my job here, it's kind of funny. I look back now and I'm like, "Wow, I actually did do a lot of that when growing up."

I used to skateboard all the time. I used to have a video camera with me. All the time is just videotape, skateboarding. It's the same thing with motorcycles and parts and doing tech tips and whatever other things. It's just translated a little differently. I never put two and two together. Wow, that can be a passionate life of mine and a thing when I was younger. I wish I would have found it faster because doing photography and video, that's my life now. That's all I do.

New to Land Speed Racing: Knowing Nothing, Getting Ready

Tyler: We got started in racing in late 2009, early 2010. It was our first year for both of us racing land speed at the Bonneville Salt Flats. It was Bonneville Speed Week 2010.

Todd: Tyler wanted to do land speed racing in Bonneville, where you go three miles flat-out full throttle, and then shut down trying to set a speed record.

Tyler: I know I got interested because I'd go and hang out with my friend, Wes White, Four Aces Cycle in Pacoima, California. Stay asleep on his couch, and work with him in a shop for a week, here and there, learn from him. He raced at Bonneville for several years. His enthusiasm was infectious. He got me really interested. I remember in one trip in particular, I had-- Actually, it was the start of this bike, but I was building it as a chopper and I came back from that trip and I thought this is the perfect basis for me to build a race bike. Kyle and I started talking about going to Bonneville which I think that point was like 10 months away or something.

Kyle: No problem, build two bikes in 10 months. Easy.

Tyler: Knowing nothing, getting them all ready, learning the rules, the safety, inspection rules, so we could pass tech, make sure the bikes were up to snuff and allowed to race. Actually, a funny story, I was thinking about this the other day, is that at that point, 2010, I'd been riding motorcycles for 12 years, maybe, and Kyle, probably about the same. To race at Bonneville, you have to have your motorcycle endorsement. I didn't have a motorcycle endorsement.

Getting Motorcycle Endorsement After More Than a Decade of Riding

Kyle: Neither did I. I never even got my temps honestly before--

Tyler: I would give my four months once in a while and it's good for a year and then it would expire. I get pulled over once in a while. The police officers were always cool. They never seemed to not know or care. I don't know what it was, but I'd never gotten a ticket on a motorcycle. I've been pulled over a number of times, so I just never bothered getting my motorcycle endorsement.

To race, you had to. We actually took the Ohio Rider Safety Course, which is like $25 and you go for a weekend. It was fun. I learned some things, whatever. I was messing around on motorcycles for a weekend, but it was just funny going to get a license after more than a decade of riding, having like a full-on motorcycle company at that point. Which I do know why they take the motorcycle riding course, because I didn't own a single, legal motorcycle.

Kyle: Yes. You'd have turn signals and mirrors in the whole deal.

Tyler: Riding like, hand shift, raked out, freakin' Triumph, or like bikes with no mufflers, no gauges, no turn signals.

Kyle: You can't ride a bike if you don't have a license.

Tyler: Right, so always motorcycles were: A, not the right geometry to be banging out, figure eights inside of a parking spot or whatever you're doing the test, or simply they didn't pass the legal requirements. I think that's why I never went get a license. Most of the people I knew were also riding like chopped up bikes at, wouldn't pass the safety inspections to be road-legal. We started building race bikes, me building this bike, and Kyle building--

Built a '68 Triumph and Did a Rookie Run

Kyle: I built a '68 Triumph.

Tyler: Right. That was in the office of Lowbrow and my sign company, which was the outbuilding behind my house in Hinckley. I remember, I was sitting out of the dust where I had my computer and I'd been doing work, Kyle was literally assembling his race bike on the carpet on the little space behind my desk.

Kyle: The only place I could find six, eight feet. We only had one [crosstalk] cycle list, a lift rather.

Tyler: This was on a lift on the work bay, a little, tiny work bay I had next to the office.

Todd: Tyler approached me and he said, "Hey, Todd, I want to build a dual engine race bike and use Triumph engines." I said, "That sounds like a good idea because I'd like you to help me." Then I go, "Cool, I'll help. It sounds like fun." The fateful day in the Middle Bay Workshop at the Medina warehouse, we had the bike ready to run. Tyler said to me, "How in the heck are we going to cook these two engines together and make it all work?"

I go, "Well, we had a piece of chain sitting on the workbench because we had welded sprockets to each other to attach the two engines together with a 530 single-row chain." I said, "Wait, let me go get a special tool for timing the engines." I went to my desk around the corner against the wall in the Parts Department and I grabbed a pencil. I cut the end of it off, and I shoved it in the spark plug hole. I took all the plugs out of both motors and I put it in the plug hole.

I rotated the motor until the piston was all the way at the top which is top dead center. I went to the second motor and I did the same thing, I put the chain on. I said, "All right, fire it up." Everybody was all nervous. They're like, "Are you sure? Is this going to work?" I'm like, "Well, no. Pretty quickly if it's not right." Had an electric starter motor with a battery to turn the engines over, there's a big nut on the end of the crankshaft. Fired it up, bam, thing ran perfectly. That's a pretty joyous day in the Lowbrow workshop.

Tyler: I don't know, it was just steep learning curve. We went out there and raced. I had an absolutely blast and came well-prepared, but it's hostile environment, it's high altitude. The weather can be bad. The salt was actually good those couple years—

Kyle: [unintelligible 00:34:35] gremlins for five days. My first six runs, I couldn't go above 50 miles an hour.

Tyler: Ignition was breaking out.

Kyle: Yes, the bike would just cut out, pop and you have to do a rookie run there just to prove that you can handle the bike, go the full length of the course. Finally, I think literally like the fifth or sixth run, I just sat up one-handed, just pop, pop, pop, pop, pop, pop, for two miles just to get it over with.

Tyler: Just to get it over with.

Kyle: Just to get it done.

Just Went Out There and Did It, Made It Happen

Tyler: We were gone two weeks, drove out in an old RV. I'd bought in mid early '90s, 23-foot little RV. That way, we use that as our chase vehicle. We could be like in line for two hours in the blazing sun in Utah, but eating bean burritos and air conditioning with our race leathers on.

Kyle: With one crew member.

Tyler: Yes, our dad.

Kyle: One crew member for two people which--

Tyler: In a high-stress environment.

Kyle: Yes. It was like with family on top of it. It was a fun year. [laughs] At the time, I think there was some anger. [laughs]

Tyler: Yes, a little. I qualified for record that year and then bent a valve on the backup run, couldn't back it up. Needless to say, the whole process was like there's no question, like, "This is an amazing way to spend some time and effort and the year leading up to it." Even though it's 2,200 miles driving from here to Utah--

Todd: A lot of people are going out to the Salt Flats, trying to attain that, getting that speed for that record. It was pretty amazing that with Tyler's drive and determination, he just went out there and did it, made it happen.

Tyler: It's amazing to be racing at the same event where it's literally the fastest motorcycles and the fastest cars on the planet, are racing currently and have raced. The ability to just walk in the pits and walk up to--

Kyle: Challenger 2.

Tyler: Yes.

Kyle: Then watch it go by a 453 miles an hour.

Tyler: You walk up and talk to these guys, check out their car, they're friendly. Actually, they welded up my oil tank.

Kyle: That was speed demon.

Tyler: That was speed demon, one of the other fastest cars in the world, over 400 miles an hour. I had a crack in my oil tank due to my old TIG welding, [chuckles] just from ibration. The fact is, I've got this little Triumph that's doing 125 miles an hour, had a crack on my oil tank and those guys stopped what they're doing to help me out because they had a TIG welder. That's just like the spirit of the sport.

You can have a guy with a crusty pickup truck and his son, and they're racing some old Honda or whatever, that cost some a few hundred bucks, and they're there having as much fun potentially or more than guys that have 30 guys in a mess hole and the world's fastest car. What's nice is it's that whole gamut. It's a real motor sport but the entry level can be so low depending how you decide to enter it. We went out not knowing what we're doing and had a blast the first year.

Year Two, Went Back, and Recorded

Kyle: Year two, went back, ready to go, we both recorded multiple times that year. We set the bar pretty high there, going back second year. Some people go back 10 years and never hit that record, so we started pretty strong.

Tyler: Yes, it was good. The racing came that was just like pure personal passion and focus, but it does tie into our business in that I think people see and respect that. We do that for fun. Again, it comes back to what I was saying as far as we are our customers with the same drive.

Doing What's Right: Lowbrow Customs Continues to Grow

Todd: I believe that same drive and determination is what is allowing Lowbrow Customs to continue to grow as a company and still maintain. A lot of people think we're this giant company like J&P Cycles, Dennis Kirk, RevZilla, or something. We're not.

Kyle: The amount of customers that come out and show up on the salt because they live in the area, the amount of customers that have gone out and built race bikes of their own because they saw us do it. Stuff like that is hugely gratifying. It's super cool somebody to tell you that you inspire them to do something. We were just chasing something we wanted to do.

Tyler: I could speak to the future of Lowbrow in that no freakin' idea. There's never been a game plan, it's never been like, "We're going to have this many parts, we're going to make this much money, we're going to do anything." There's no game plan, I assume being there for a long time.

Kyle: Any time we've ever made a business plan or five-year goal, it's just been completely shattered one way or another.

Tyler: Right. We never know what trajectory we're going to go on. Three years ago, I would never imagine we're in the nice building we're in now. What I know personally is that if I'm excited for what we do and I'm happy on a personal level as well as work level and having fun. Then I'll just keep doing it. It's like a constant flux and it always has been, because we're uneducated. [laughs] We're like, "We don't know what we're doing."

Kyle: Well, I know what I'm doing.

Tyler: Just literally flying by the seat of our pants, going like, "Okay Hey, this seems like a good idea." It's something I think has been a huge positive in many ways over the years because I can't tell you how many times I've done something and people are like, "Are you freaking crazy? What are you doing? That's never going to work." Had I listened to them, Lowbrow wouldn't exist. Had I gone to college or had more-- I'm not saying it's bad, but for me it was not the right path. It might have changed the way I did things because the way Lowbrow was built is not traditional. It was slow because it was-

Kyle: It was bootstrap.

Tyler: It was bootstrap with, I didn't have any money, I didn't have any help.

Kyle: There was no loans. It was rolling that profit back.

Core Beliefs at Lowbrow Customs

Work Your Ass off, Put the Time In

Tyler: Right. It was like, "Cool. I make 20 bucks. Let sell some stickers." Cool, 17 of that is going to go back into the company. People said, "You guys are lucky." I can't say there's no luck involved. The timing was great early eCommerce years and this and that, but it was just hard work. The motorcycle industry is tough. I know. Only a handful of people that make a full time living in the motorcycle industry.

My advice, whether it's painting or building bikes, or starting a parts company like Lowbrow or whatever. My advice is work your ass off, put the time in. I know all my friends were at the bar, going snowboarding or this or that, and I was coding HTML and editing photos in Photoshop, and writing product out. You have to pay to play I guess. [laughs]

Learning New Skills and Pushing Continuously

Obviously you want to work smart, but the reality is, it's hard frickin work. This is our life's work, literally. Fabrication in general, making things, working, learning like I definite professional amateur. I build bikes, for fun not for anyone else. I typically working on race bikes like this one, or I'm building a new one right now. What I enjoy is learning new skills and pushing continuously.

Mikey: He's pushing always to like, "Better yourself." He never shies away like, "Hey, man, this project might take me two weeks. I don't know what I'm doing?" "Well, take the time learn it, go at it, do it." He's always supportive. He's not like, "No, I really need this done now." He's not one of those guys that's hard ass and trying to push you in a wrong way. He's always supportive and letting you learn and teach you things that he knows, and it's great.

We Are Our Customers

Kyle: We are the customers, we're the guys in the garage. We're building bikes. We like all different types of motorcycles, we like racing. A lot of times when we're looking at carrying parts or designing parts, we are looking for the solutions we need. What we would want as a customer, racing everything is based off of that.

Curation of Motorcycle Parts & Accessories, Quality and Fit Guaranteed

Tyler: Some of the things we focus on are producing extremely well designed, thoughtful, high quality products that are also manufactured efficiently where we can sell to our customer at a really good price. That's employing local people using US steel or aluminum, or what have you, and make parts that are just really high quality, a great fit. The customer is going to be really happy, they're going to be durable.

It's a long term view, it's not looking to sell a bunch of stuff and make a bunch of money this week. The time the effort, the brain power we put into developing these products. The hard work is in all of that design work, figuring it out. The end product might look simple, but in many cases it will be like years of work into some of the more complex products to get a dial to the point that it's shipped to the customer. They watch our install video or read the install blog post, put that part on a Saturday afternoon, and they're back on the road.

It seems so cotton dry, but there's a ton of blood, sweat and tears that goes into that stuff to make it that easy for the end user. We do curation. We've built that trust with our customers over the years, where if they buy something from us, they know that it's going to be what we say it is and they're going to be happy with it. They also know though if they do have a problem with some product they purchased, we're still going to be around in 30 days or in three years.

Kyle: Or 90 days.

Supply Our Customers With Astounding Customer Service

Tyler: Yes, right. We offer free motorcycle tech support on all products even, it's something we don't sell. You can call us we do our best to help our customers over the phone, via email solve problems and move forward. Just instead of doing a bunch of print advertising, I'd rather spend that money on giving customers direct support, and fast shipping, and all these other things that make their experience better.

Something I say frequently to people is, 'a rising tide floats all boats'. What's good for the motorcycle industry and what's good for our customers and motorcycle enthusiasts, it all comes around and it's good for us. Which is why we put a lot of time and effort into doing free events, free shows, camp outs, free swap meets. Creating a lot of media we put out for free. I think that has long lasting implications. The main thing is doing what's right. Honestly what we believe in and not ever sacrificing our core beliefs for money, because when you get corrupted like that, in my opinion. What's the point? To me, it would ruin everything.

We Care

Kyle: Well, I think one thing with all the employees here is everyone really genuinely cares. Every package we sell and ship out the door, every part we add every part we design, and we actually care. We're not just adding in a book of miscellaneous junk that everyone else carries. We want your experience from the time you order on our website to that package showing up at your door, a phone call in for tech support, or anything and we want it to be just top notch.

Kaitie: I hope it stays small like this, because it's awesome. People seem to really appreciate small business like, DIY guys type of thing. I think it's perfect how it is, and I just see it getting better and better.

Get to Know Your Customer, and Your Market

Kyle: One thing we're very aware of here is just the future. We're always watching what is going on in the world, in the market. We try not to jump on trends. There's enough guys doing that and it's not about a quick buck. We're in this for the long haul.

Tyler: What we do isn't for everyone. It's not supposed to appeal to every person who rides a motorcycle, and that's excellent. I don't want to appeal to everyone. Those people we resonate with are our die hard supporters and customers and they keep us doing what we love, and that's just how I like it.Related Products