Here at Lowbrow Customs I handle new product design. I thought that some of you out there would enjoy seeing a bit of the process behind the custom motorcycle parts we sell. This article will share the entire process behind our AMF Grips and Champion Grips, from rough idea to finished product.

We engaged ODI in Riverside, California, USA to manufacture the tooling and produce grips for us. ODI has been making bicycle and motorcycle grips (as well as other related parts) for decades, and we are excited to work with them on fun projects such as these new Lowbrow Customs motorcycle grips.

WATCH VIDEO: HOW IT'S MADE - LOWBROW CUSTOMS GRIPS

How Do We Come Up With Custom Motorcycles Handlebar Grips Ideas

I started out years ago drawing things by hand, and then moved to scale drawings in Adobe Illustrator, saving PDF files and providing them to various vendors, such as machine shops, laser cutters, and the like.

A few years back I took night classes at the local community college (Tri-C in Cleveland, Ohio) for SolidWorks, which is 3-D CAD (computer aided design) software. This really upped my speed and capabilities and allowed me to take ideas and turn them into mathematical, tangible models.

Original sketches for the Champion Grips

However, I often still start out with a quick napkin sketch to get the idea out there and visible, and to decide if it looks good and makes sense.

In the case of the AMF and Champion Grips, I worked with our design engineer Dowie Soetenga on the SolidWorks end of things. The complex design of the AMF Grip swoop on the compound curves of the grip was pushing the limits of my abilities.

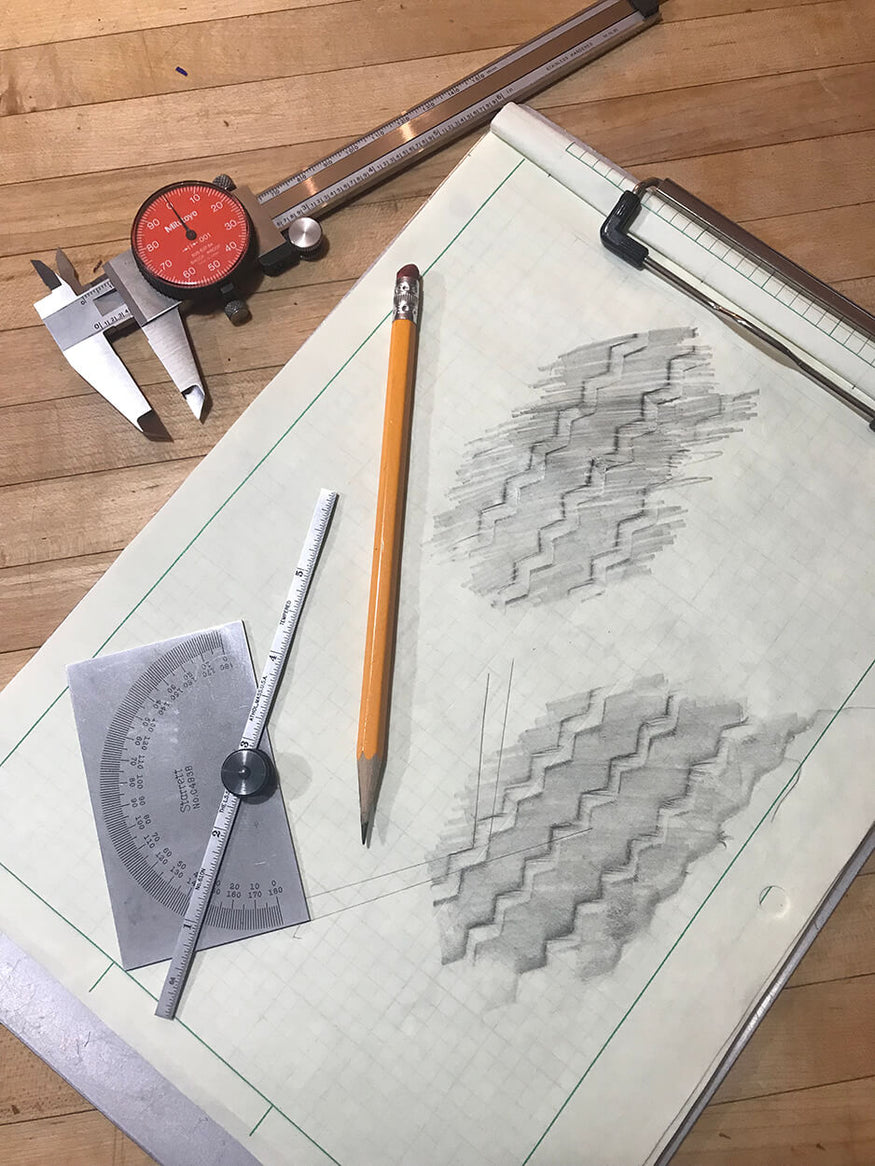

Champion Grips are made to match the tread on vintage, champion-style, bias ply car tires. The thread is similar to that of a Coker Firestone Deluxe Champion motorcycle tire, popular on vintage motorcycles and choppers. Coker also produces Firestone Deluxe Champion tires for cars which are popular on classic hot rods. Here is one of the original sketches for the Champion Grips. The original was thrown away long ago, so this cell phone photo is all that remains.

AMF Grips

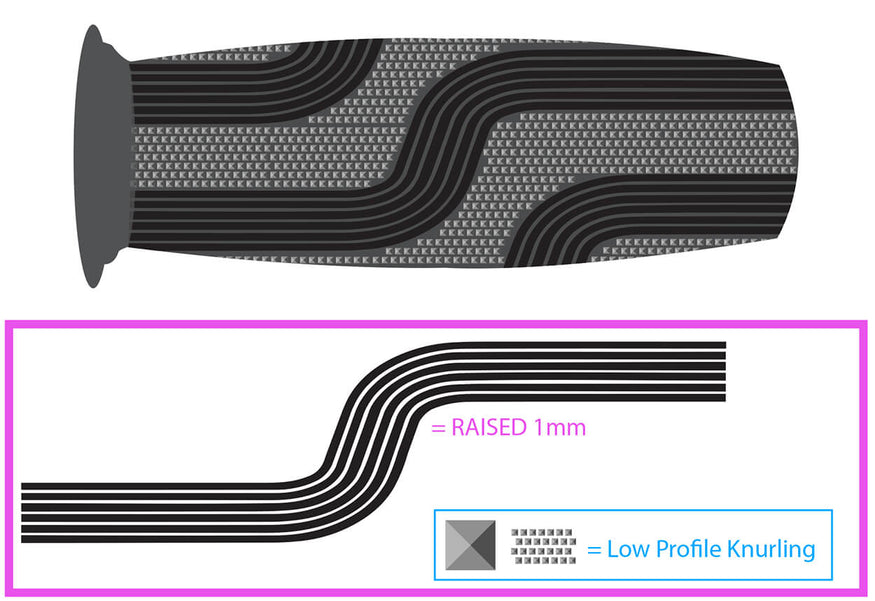

In the case of the AMF Grips, I discussed the idea with Jason (known here at Lowbrow and everywhere else as Longhair, as he is a long-time metalhead with.. you guessed it. Long hair!) and he quickly made this mockup in Adobe Illustrator based on the general shape of our Knurled grips.

The first mockup of the AMF Grips in Adobe Illustrator

With the basic ideas flushed out it was time to start modeling the grips in SolidWorks. The AMF Grips have a profile and detail inspired heavily by vintage Norton Dunstall handlebar grips. The ribs and waffle pattern give a dense yet most comfortable motorcycle grip, and I thought they were the perfect contrast for the swoop pattern that would be present on either side of the grip.

While the design idea was solid and straightforward, the modeling of these patterns on the compound curve of a grip was a challenging task. However, the 3D model of this grip didn’t need much revision besides adding the ‘LOWBROW CUSTOMS’ branding to the end cap.

The animated image above shows the Lowbrow AMF Grip design as seen in SolidWorks.

Champion Grips

For the Champion Grips, a rubbing (with paper and pencil) was taken of a vintage, Champion-style, bias-ply car tire. The thread is similar to that of a Coker Firestone Deluxe Champion motorcycle tire. This made it easier to accurately measure and replicate the tire tread in SolidWorks. It took a couple of revisions in SolidWorks to get the styling on this grip just right.

Right styling on the Champion Grips

Changes included playing with the amount of zig-zags, as well as the overall length of the grip, and the addition of the 1/16” grooves at each end, which matches the termination grooves on the tires these are inspired by.

Lowbrow Customs branding was added to the end cap of the motorcycle grip, as well as to the face of the grip near the flange. These changes were solely to get the appearance of the grip to be ‘just right’.

The animated image above shows the Lowbrow Champion Grip design as seen in SolidWorks.

MakerBot 1st Generation 3D Printer to Upgrade for Lowbrow Customs Motorcycle Grips

These days we have the benefit of 3-D printing, aka rapid prototyping, samples of the grips before having tooling made. Once the tooling is made, that is it! If you don’t like a small detail, or the size is just a little too big or too small, you are either stuck with it or you remake the tooling, which costs the same as a real nice motorcycle, an OK boat, or a really crappy airplane.

Here at Lowbrow we have a relatively inexpensive, first-generation MakerBot that does the job for quick plastic (PLA) prototypes. I went ahead and printed a sample of each grip so I could see it in real space, as opposed to on a monitor, and feel it in my hand.

With the plastic prototypes getting my OK, we went ahead and had a set of rubber rapid prototypes made by a 3-D printing company. With their high end equipment we were even able to specify the durometer, or hardness of the rubber, of the samples, as well as get them in black.

Sample of Lowbrow Customs AMF Grips from MakerBot 1st Generation 3D Printer, printed in PLA (plastic) on the far left, with the rubber rapid prototype in the center, and actual injection-molded grips on the right.

These injection-molded grips on the far right in the photos above were the tooling samples, the first grips run in our new tooling to check the quality, finish, and performance of the tooling.

With the rapid prototypes to our liking it was time to get the tooling into production. We sent our final files over to ODI, discussed the project in detail, and received quotes on the necessary tooling as well as estimated per-piece pricing on the Lowbrow Customs motorcycle grips and packaging. We approved the tooling quote, sent over a purchase order and deposit and ODI got to work on our tooling.

Tooling design of Lowbrow Customs Champion grip

Lowbrow Customs Grip tooling in the process of being checked

In these photos you can see the Champion Grip tooling in the process of being checked over during the manufacturing process.

To get the material to flow properly and completely fill the tooling, the durometer of the material might need tweaked, or the size of the injection molding, or the cycle time of the machine. Some testing is necessary to determine the right combination for the grip design to ensure the best results. ODI performed a series of test runs of grips with our new tooling to determine the right combination to get the perfect finish for each style Lowbrow Customs motorcycle grip. We always aim for the highest possible quality, even if it means increasing the cycle time for instance, and increasing the cost of the finished product.

Design A Motorcycle Grips Box

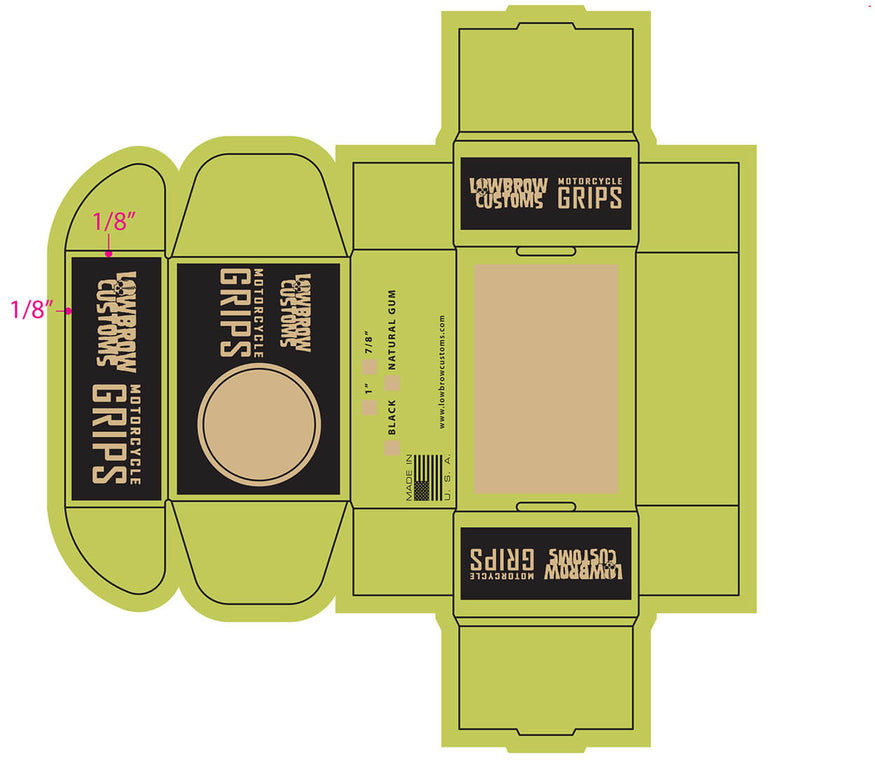

While the tooling was getting manufactured and the tooling dialed in, we proceeded with the box design. We decided to design one new grip box that could be used for a variety of designs, keeping the cost down as we could print a larger run of one box design, instead of a series of small print runs of individual designs.

The design of new Lowbrow Custom grip boxes

Here you can see the design of our new grip boxes. The brown circle on the top of the box is a die-cut hole, which allows the style and color of the grips to be seen without opening the package. It also just looks cool when the final product is packaged.

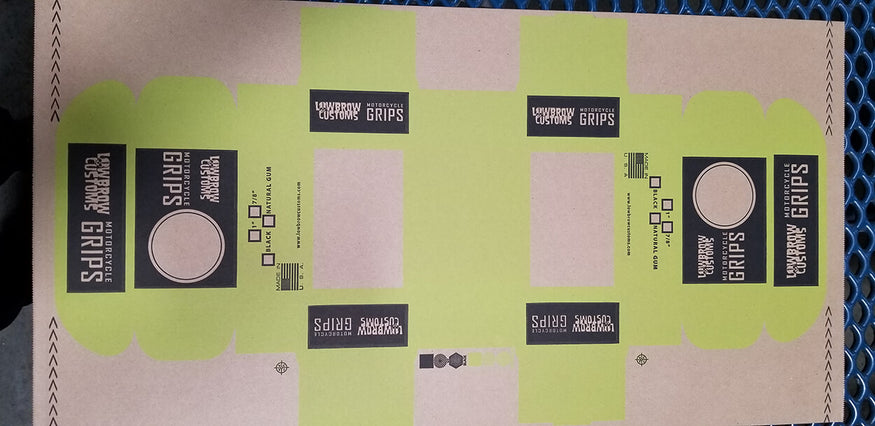

Design of Lowbrow Customs Motorcycle Grips Box printed

This is a photo of one of the first boxes printed, which was sent over for my approval. This is actually two boxes printed on one piece of kraft brown cardboard. The boxes are then die cut to their final shape, ready to be used.

Handlebar Grips Manufactured by Injection Molding Machines at ODI

Lowbrow Customs Champion Grips and Injection Molding Machines

Here you can see the Lowbrow Customs Champion Grips and associated tooling. This is one of the injection molding machines at ODI. In this photo you can clearly see that these are the black grips. For the Natural Gum version, the machine is cleaned and prepped for the alternate color material.

Handlebar Grips Manufactured by Injection Molding Machines at ODI

Here an ODI employee uses an air nozzle to get the freshly made Champion Grips off of the dowel. The dowel is the piece of tooling that forms the proper size opening in the grip replicating a handlebar. The dowels were custom made for Lowbrow Customs to provide the proper amount of interference to ensure that these custom hand grips for motorcycles are a tight, secure fit on motorcycle handlebars.

Fresh Champion Motorcycle Grips are filling the shelves as they come out of the injection molding machine.

Pack The Motorcycle Handlebar Grips In The New Box

Packing the motorcycle handlebar grips in the new box.

Next up, the printed, die-cut boxes are folded into shape, the appropriate check boxes are marked on the side for color and size grip, and a pair of grips inserted. They are now ready to be packed into cases, stacked on a pallet, and sent off to Lowbrow Customs in Brunswick, Ohio, USA!

Packing the motorcycle handlebar grips in the new box.

I was working in the warehouse when our AMF Grips and Champion Grips arrived at Lowbrow Customs. They came from ODI in California and showed up a day early.

AMF Grips and Champion Grips arrived at Lowbrow Customs

I am always so excited to see a new product design through to the end. The AMF and Champion Grips were started in late 2019, and just over 6 months later, they are a reality. I find it very fulfilling to see our products out 'in the wild' and know that these will be popular. I look forward to seeing them on bikes all over the world!

I hope you enjoyed the motorcycle handlebar grips introduction bit of insight into the design process that happens 'behind the scenes' for each and every new part we enjoy. If you’d like to replace your motorcycle grips, see our post how to install custom motorcycle grips with a detailed guide.

- Tyler Malinky

Founder & CEO

Lowbrow Customs

Photos of Lowbrow Customs AMF Grips and Champion Grips on Motorcycles

Jay Cagney's Harley Ironhead Sportster with AMF Grips on the beaches of San Francisco.

Ken Carvajal's Panhead with AMF Grips

Close up with Heath Braun's Shovelhead.

Ken Carvajal's Harley Shovelhead chopper with Champion Grips.

Heath Braun's wild Honda chopper with Champion Grips.

Champion Grips on Jay Cagney's Harley Shovelhead.

If you'd like to read more about motorcycles, see our events-features blog collection. Thanks for reading!

Leave a comment at the bottom of this article:

Related Products